PEB vs RCC: The Truth Industrial Owners Must Know Before Building | ACCO Engineering (2025 Guide)

Introduction to ACCO Engineering

ACCO Engineering is Pakistan’s leading company specializing in Pre-Engineered Buildings (PEB), industrial steel structures, warehouse construction, cold storage solutions, and turnkey factory development. Based in Lahore, ACCO Engineering delivers modern, fast, and cost-effective industrial construction solutions across Pakistan.

With decades of professional experience and hundreds of completed steel structures, ACCO Engineering is trusted by manufacturing units, logistics companies, textile mills, pharmaceutical plants, and agricultural warehousing operators.

Our core expertise includes:

Pre-Engineered Steel Buildings (PEB)

Industrial Warehouses

Cold Storage Structures

Factory Buildings

Steel Sheds & Logistics Facilities

Turnkey Industrial Design & Construction

Heavy Industrial RCC Structures (where required)

Today’s industrial owners are confused between two major construction systems:

Pre-Engineered Buildings (PEB) vs Reinforced Cement Concrete (RCC).

This blog explains the truth—what is the right choice in Pakistan’s industrial environment, cost, time, durability, and long-term performance.

Introduction to the Topic: PEB vs RCC — Why This Comparison Matters

The debate of PEB vs RCC has become one of the most searched topics in Pakistan’s construction industry, especially after the rising demand for:

Warehouses

Industrial sheds

Cold storage buildings

Manufacturing plants

Godowns

Logistic hubs

Textile and packaging units

Industrial owners want:

Faster construction

Lower cost

Long-term durability

Flexibility for future expansion

Traditional RCC buildings are strong but slow and expensive.

PEB steel structures are modern, efficient, and 3X faster to construct.

This blog provides a complete comparison, based on Pakistani industry conditions, cost trends, and real-world performance.

Understanding PEB and RCC

What is PEB (Pre-Engineered Building)?

A PEB is a steel structure manufactured in a factory and assembled on-site.

It includes:

Primary steel frames

Secondary members (purlins/girts)

Roof & wall sheeting

Bracing system

Bolted connections

Key Features of PEB:

Lightweight steel structure

100% factory fabricated

On-site installation without welding

Low maintenance

Best for large spans (40ft–250ft)

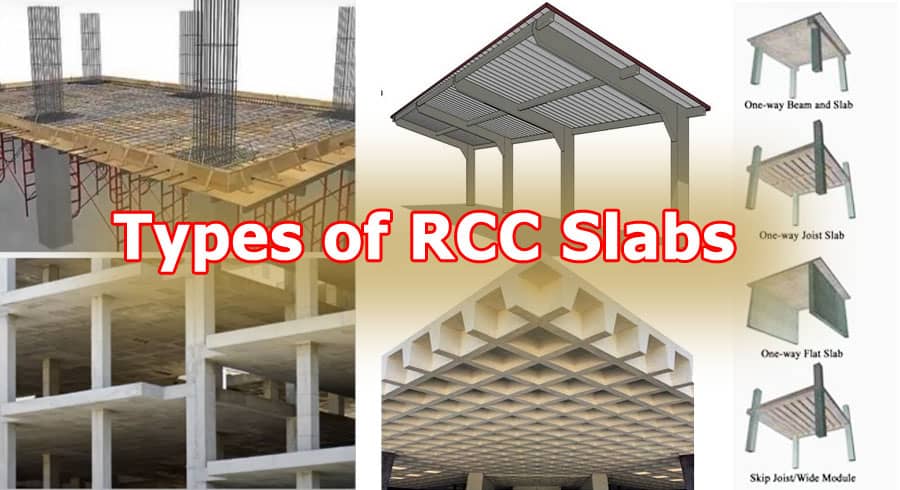

What is RCC (Reinforced Cement Concrete)?

RCC is a traditional construction system based on:

Concrete columns

RCC beams

Slabs

Masonry walls

Key Features of RCC:

Very strong and durable

Best for multi-storey buildings

More expensive

Time-consuming construction

PEB vs RCC (Full Technical Comparison)

1. Construction Speed

PEB:

3–4x faster

100% factory manufacturing

Only bolt-to-bolt assembly

A 50,000 sq ft warehouse erects in 45–60 days

RCC:

Very slow

Curing time required

Labour-intensive

Same warehouse takes 8–12 months

Winner: PEB

2. Cost Comparison

PEB Cost in Pakistan (2025):

Rs. 1,400–2,400 per sq ft depending on height & design

No shuttering or curing cost

Lower labour cost

Lower foundation cost

RCC Cost in Pakistan (2025):

Rs. 3,200–5,000 per sq ft

Requires heavy foundations

Higher labour cost

Additional finishing & plaster cost

PEB saves 30–40% compared to RCC.

Winner: PEB

3. Structural Strength

PEB:

Flexibility in seismic zones

High wind resistance

No cracks or shrinkage

High tensile steel

RCC:

Heavy and rigid

Performs well under compression

Can crack under seismic loads

Requires maintenance

Winner: Depends on project type

(PEB better for industrial; RCC better for multi-storey buildings)

4. Span Capacity

PEB:

Clear spans up to 250 ft

No internal columns

Maximum usable area

RCC:

Span limited to 25–35 ft

Requires internal columns

Winner: PEB

5. Maintenance

PEB:

Minimal

Only repaint after 10–12 years

No plaster, no leakage issues

RCC:

Plaster cracks

Leakage & seepage issues

Structural maintenance needed

Winner: PEB

6. Flexibility & Future Expansion

PEB:

Expansion-friendly

Add a new bay anytime

Easy modifications

RCC:

Extremely difficult to expand

Expensive alterations

Requires demolishing walls/columns

Winner: PEB

7. Environmental Impact

PEB:

Recyclable steel

Less waste

Controlled fabrication

RCC:

High carbon footprint

Excessive material waste

Heavy use of cement

Winner: PEB

PEB vs RCC Comparison Table

| Feature | PEB | RCC |

|---|---|---|

| Construction Time | 45–60 days | 8–12 months |

| Cost | Low | High |

| Strength | Flexible & tensile | Rigid & compressive |

| Span | Up to 250 ft | 25–35 ft |

| Foundations | Light | Heavy |

| Expansion | Very easy | Very difficult |

| Maintenance | Minimal | High |

| Earthquake Resistance | Excellent | Moderate |

| Best Use | Industrial | Multi-storey |

Which One Should You Choose? (The Truth Industrial Owners Must Know)

Choose PEB If:

You need fast construction

You need a large clear span warehouse

You need future expansion

You want lower cost

You want modern industrial architecture

You want low maintenance

You need large ventilation and skylights

PEB is the best solution for:

Warehouses

Factories

Cold storage

Logistic hubs

Workshops

Agricultural storage

Choose RCC If:

You need multi-storey construction

You need a basement

You need extremely heavy load-bearing floors

RCC is best for:

Plazas

Hospitals

Multi-storey buildings

Residential buildings

Pros and Cons of PEB

Pros

Fastest construction system

Lower cost

Large span with no columns

Future expansion friendly

Earthquake resistant

Cleaner, modern design

Cons

Steel price fluctuations

Requires technical engineering

Not preferred for multi-storey

Pros and Cons of RCC

Pros

Very strong and durable

Multi-storey friendly

High fire resistance

Cons

Very slow

High cost

Cracks, leakage, dampness

Hard to expand

Heavy foundations

Frequently Asked Questions (FAQs)

1. Which is cheaper: PEB or RCC?

PEB is 30–40% cheaper than RCC in Pakistan.

2. How long does a PEB take to build?

A 20,000–50,000 sq ft building takes 45–60 days.

3. Is PEB durable for industrial use?

Yes. PEB lasts 40–50 years with minimal maintenance.

4. Can RCC be used for large-span industrial buildings?

No. RCC cannot support large spans without columns.

5. Is PEB approved by Pakistani authorities?

Yes. Pakistan’s industrial zones and SEZs allow PEB structures.

Internal Links (ACCO Website)

(You can add your actual URLs)

House Construction in DHA Lahore

Commercial Plaza Builders Lahore

Industrial Warehouse Construction Pakistan

PEB Buildings in Lahore

Turnkey Construction Services

External Links (High Authority Sources)

construction.gov.pk — Pakistan Construction Guidelines

DAWN News — Infrastructure Updates

ArchDaily — Global Steel Building Trends

PHC & Building Codes Pakistan

WHO Safety & Industrial Standards (for environment-friendly structures)

Final Verdict

In Pakistan’s industrial climate—where time, cost, and efficiency matter—PEB is clearly the superior choice for factories, warehouses, and logistics buildings. RCC is a strong system but is only suitable for conventional multi-storey buildings.

Industrial owners who need modern, fast, and expandable construction should always choose PEB.

ACCO Engineering provides complete turnkey PEB solutions, including design, fabrication, installation, MEP, and finishing.

Call to Action (CTA)

Ready to build your industrial project?

Contact ACCO Engineering for a free consultation, design proposal, and cost estimation.

📞 Phone / WhatsApp: 0322 8000190

🌐 ACCO Engineering — Pakistan’s No.1 PEB Specialists

Related Posts

PEB Industrial Projects in Islamabad & Rawalpindi – ACCO Engineering

Industrial PEB Construction Services in Islamabad | ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.