Industrial & Commercial Pre Engineered Buildings in Pakistan – Complete Overview | ACCO Engineering

Introduction to ACCO Engineering

ACCO Engineering is a professional engineering and construction company in Pakistan, widely recognized for delivering industrial and commercial Pre Engineered Building (PEB) solutions. With years of experience in steel structure design, fabrication, and erection, ACCO Engineering has successfully completed projects across Lahore, Karachi, Islamabad, Faisalabad, and major industrial zones of Pakistan.

Our core specialization includes:

Industrial Pre Engineered Buildings

Commercial Steel Structures

Warehouses & Logistics Centers

Factories & Manufacturing Units

Power Plants & Utility Buildings

By combining modern engineering tools, international standards, and local industry knowledge, ACCO Engineering delivers cost-effective, durable, and future-ready structures tailored to Pakistan’s industrial needs.

Website: www.accoengineering.com

Email: info@accoengineering.com

Phone / WhatsApp: 0322 8000190

Topic Introduction: Industrial & Commercial Pre Engineered Buildings in Pakistan – Complete Overview

Pakistan’s construction and industrial landscape is changing rapidly. Traditional RCC construction methods are becoming time-consuming, expensive, and less flexible, especially for industrial and commercial projects.

This has increased the demand for Industrial & Commercial Pre Engineered Buildings (PEB) — a modern construction solution that offers speed, affordability, strength, and scalability.

In Pakistan, where:

Industrial expansion is increasing

Warehousing and logistics sectors are booming

Investors demand faster project completion

PEB construction has emerged as the preferred choice for industrialists, developers, and commercial investors.

What Are Industrial & Commercial Pre Engineered Buildings?

Pre Engineered Buildings are steel structures designed and fabricated in factories and assembled at the construction site. These buildings are engineered using advanced software to optimize steel usage, strength, and cost.

Industrial PEB Buildings

Used for:

Factories

Manufacturing plants

Processing units

Power plants

Heavy machinery workshops

Commercial PEB Buildings

Used for:

Warehouses

Distribution centers

Showrooms

Commercial offices

Shopping outlets

Cold storage facilities

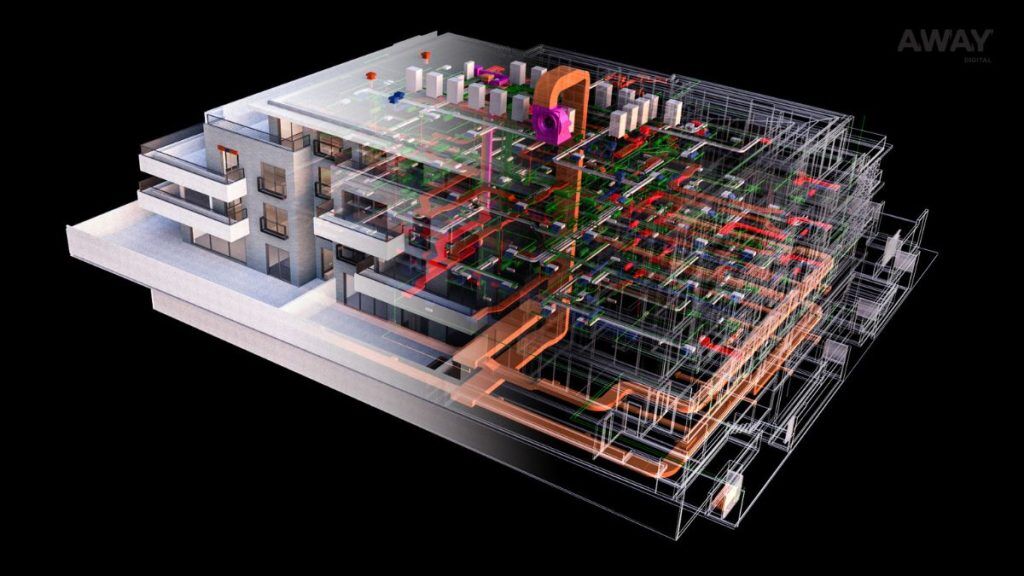

Key Components of a PEB Structure

A complete PEB system includes:

Primary Framing: Columns and rafters

Secondary Framing: Purlins, girts, bracings

Roofing System: Galvanized or insulated panels

Wall Cladding: Single skin or sandwich panels

Doors & Windows

Ventilation & Skylights

Insulation Systems

Crane Systems (optional)

Each component is designed according to load requirements, usage, and local climate conditions in Pakistan.

Why PEB Is Ideal for Industrial & Commercial Projects in Pakistan

1. Rapid Industrial Growth

Pakistan’s manufacturing, logistics, and export sectors require quick and scalable infrastructure, which PEB provides efficiently.

2. Cost Sensitivity

Industrial investors seek maximum output with minimum capital, making PEB a cost-effective alternative to RCC construction.

3. Climate & Seismic Conditions

PEB structures are engineered to withstand:

High wind loads

Seismic activity

Extreme temperatures

This makes them suitable for all regions of Pakistan.

Construction Process of PEB Buildings

Step 1: Requirement Analysis

Understanding building usage, span, height, loads, and future expansion needs.

Step 2: Structural Design

Engineering design using international standards and optimized steel sections.

Step 3: Factory Fabrication

Steel members are fabricated in controlled factory conditions to ensure precision and quality.

Step 4: Site Preparation & Foundations

RCC foundations are constructed before steel erection.

Step 5: Erection & Installation

Steel frames, roofing, cladding, and accessories are installed on-site.

Step 6: Final Inspection & Handover

Quality checks and project completion.

Cost of Industrial & Commercial PEB in Pakistan

Average Price Range

PKR 2,500 – 3,800 per sq. ft (structure only)

Civil works may add 15–25% to total cost

Factors Affecting Cost

Building size and span

Steel grade and thickness

Roofing & wall insulation

Crane systems and accessories

Project location

ACCO Engineering provides customized quotations based on exact project requirements.

Comparison: PEB vs Conventional RCC Construction

| Feature | PEB Construction | RCC Construction |

|---|---|---|

| Construction Time | Very Fast | Slow |

| Cost Efficiency | High | Moderate |

| Design Flexibility | Excellent | Limited |

| Maintenance | Low | High |

| Expansion | Easy | Difficult |

| Structural Weight | Light | Heavy |

Advantages of Industrial & Commercial PEB ✅

✔ Faster Project Completion

Projects are completed 30–50% faster than traditional construction.

✔ Cost-Effective

Lower labor cost, optimized steel usage, and reduced wastage.

✔ Large Clear Spans

No internal columns — ideal for factories and warehouses.

✔ Low Maintenance

Corrosion-resistant coatings and durable materials.

✔ Environment Friendly 🌱

Steel is recyclable and reduces environmental impact.

Disadvantages of PEB ⚠️

❌ Design Finalization Required Early

Late changes can be expensive.

❌ Skilled Contractor Required

Poor engineering can affect structural performance.

❌ Limited Residential Use

Mostly suitable for industrial and commercial projects.

Applications of Industrial & Commercial PEB in Pakistan

🏭 Manufacturing Factories

📦 Warehouses & Godowns

🚚 Logistics & Distribution Centers

🏢 Commercial Offices

🏬 Showrooms & Malls

⚡ Power Plants

🏥 Hospitals & Utility Buildings

Why Choose ACCO Engineering for PEB Construction?

ACCO Engineering ensures quality, affordability, and reliability through:

Experienced structural engineers

Optimized steel design

High-quality fabrication

Timely project delivery

Nationwide project execution

We handle projects from concept to completion.

Frequently Asked Questions (FAQs)

1. What is the lifespan of a PEB building?

A well-designed PEB building can last 25–50 years or more.

2. Are PEB buildings safe for heavy machinery?

Yes, PEB structures are designed for crane loads and industrial equipment.

3. How long does PEB construction take?

Typically 6–12 weeks, depending on project size.

4. Can PEB buildings be expanded later?

Yes, future expansion is easy and cost-effective.

5. Is PEB suitable for commercial buildings?

Absolutely. PEB is ideal for warehouses, offices, and showrooms.

Internal Links (Suggested)

Industrial Shed Construction in Pakistan

Warehouse Construction Services

Commercial Plaza Builders Lahore

(Use these as internal website links)

External Links (Suggested High-Authority Sources)

Pakistan Engineering Council (PEC)

DAWN News – Construction & Infrastructure

ArchDaily – Industrial & Steel Architecture

Image Suggestions with Alt Text

Image: Industrial factory PEB structure

Alt Text: Industrial Pre Engineered Building in PakistanImage: Commercial warehouse steel building

Alt Text: Commercial PEB warehouse by ACCO Engineering

Final Verdict / Conclusion

Industrial & Commercial Pre Engineered Buildings are revolutionizing construction in Pakistan. They offer unmatched benefits in terms of speed, cost, durability, and scalability, making them the ideal solution for modern industrial and commercial needs.

If you are planning a factory, warehouse, or commercial facility, choosing PEB construction with ACCO Engineering ensures long-term value and professional execution.

Call to Action (CTA) 📞

Planning an industrial or commercial PEB project?

👉 Contact ACCO Engineering today for a free consultation!

🌐 Website: www.accoengineering.com

📧 Email: info@accoengineering.com

📱 Phone / WhatsApp: 0322 8000190

ACCO Engineering – Engineering Strength. Building the Future.

Related Posts

Best Pre-Engineered Building Company in Pakistan – ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.