Perfect Industrial Layout That Boosts Production — Proven Design

Perfect Industrial Layout That Boosts Production — Proven Design

Introduction to ACCO Engineering

ACCO Engineering is Pakistan’s trusted name in industrial planning, factory design, PEB steel structures, and turnkey industrial solutions. Located in Lahore, ACCO Engineering delivers world-class industrial design services to factories across Punjab, Sindh, KP, and industrial zones nationwide.

With strong expertise in sports facilities, leisure infrastructure, industrial layouts, and engineering design, ACCO Engineering ensures every project is built on efficiency, safety, and long-term productivity.

From new industrial plants to complete factory upgrades, ACCO Engineering specializes in Industrial Layout Design that reduces waste, optimizes workflow, and boosts production output.

📧 Email: info@acco.com.pk

🌐 Website: accoengineering.com

Introduction to the Topic

A factory’s success depends heavily on how the internal layout is planned. A poorly designed layout causes delays, material handling issues, worker fatigue, and low productivity.

A perfect industrial layout ensures:

Smooth material movement

Faster production

Better use of space

Safer operations

Lower operating costs

In Pakistan’s competitive environment—especially in textile, food, pharmaceutical, auto parts, sports manufacturing, and engineering sectors—companies must adopt modern layout strategies to stay profitable.

This article explains how a well-designed layout boosts production and why ACCO Engineering provides some of the most reliable industrial design solutions in the country.

What Is Industrial Layout Design?

Industrial Layout Design is the strategic arrangement of machinery, workstations, utilities, workers, and material flow inside a factory.

Its goals include:

Reducing waste

Improving efficiency

Maximizing output

Ensuring safety

Lowering production costs

A perfect layout makes every movement count—nothing is extra, nothing wasted.

Types of Industrial Layouts

1. Product (Line) Layout

Ideal for mass production where processes move in a sequence.

Used in: packaging plants, bottling lines, textile mills.

2. Process Layout

Machines grouped by function.

Used in: engineering workshops, machine shops.

3. Fixed-Position Layout

The product stays in one place; resources move around it.

Used in: heavy machinery, fabrication.

4. Cellular Layout

Workcells arranged for similar operations.

Used in: lean manufacturing.

5. Hybrid Industrial Layout

A smart mix of multiple layouts—most modern factories use this.

Key Components of a Perfect Industrial Layout

🔹 1. Efficient Material Flow

A straight-line flow reduces delays and handling cost.

🔹 2. Strategic Machine Placement

Planned based on machine capacity, vibration, cycle time, and safety.

🔹 3. Space Optimization

Using vertical/horizontal zones, mezzanine floors, and racks.

🔹 4. Worker Movement Control

Shorter travel distance = higher productivity.

🔹 5. Safety & Standards Compliance

Based on OSHA, PEC, and environmental guidelines.

🔹 6. Utility Management

Proper planning of electricity, HVAC, compressed air, and drainage.

🔹 7. Warehouse & Inventory Planning

Clear zones for raw materials, WIP, and finished goods.

🔹 8. Future Expansion Space

Smart layouts keep room for new machines and production growt

Traditional Layout vs. Modern ACCO Engineering Layout

| Feature | Traditional Factory Layout | ACCO Engineering Modern Layout |

|---|---|---|

| Material Flow | Random & congested | Smooth, straight-line |

| Space Use | Wasted areas | Optimized with zones |

| Safety | Basic | International-standard |

| Productivity | Medium | High-output focused |

| Energy Efficiency | Low | Smart & controlled |

| Flexibility | Difficult to change | Easy to expand |

| Worker Movement | Long & tiring | Short & planned |

Pros & Cons of Industrial Layout Design

✔ Advantages (Pros)

🚀 Higher production output

🔄 Faster workflow with fewer stoppages

💰 Reduced labor & material handling costs

🧍 Less worker movement and fatigue

⚙️ Better machine utilization

🛡 Improved safety

📦 Well-managed inventory

🔧 Easy maintenance

📈 Supports long-term industrial growth

❌ Challenges (Cons)

💸 Initial planning investment

⏳ Time required for proper analysis

👷 Worker training needed

🧭 Resistance to change

📦 Requires data on machinery & process

Industrial Layout Design Process by ACCO Engineering

ACCO Engineering uses international methodologies:

1. Site Survey & Measurements

Laser and drone measurements for accuracy.

2. Production Process Mapping

Understanding how the product flows from raw to finished.

3. Machine Study

Cycle times, spacing, vibration, access areas.

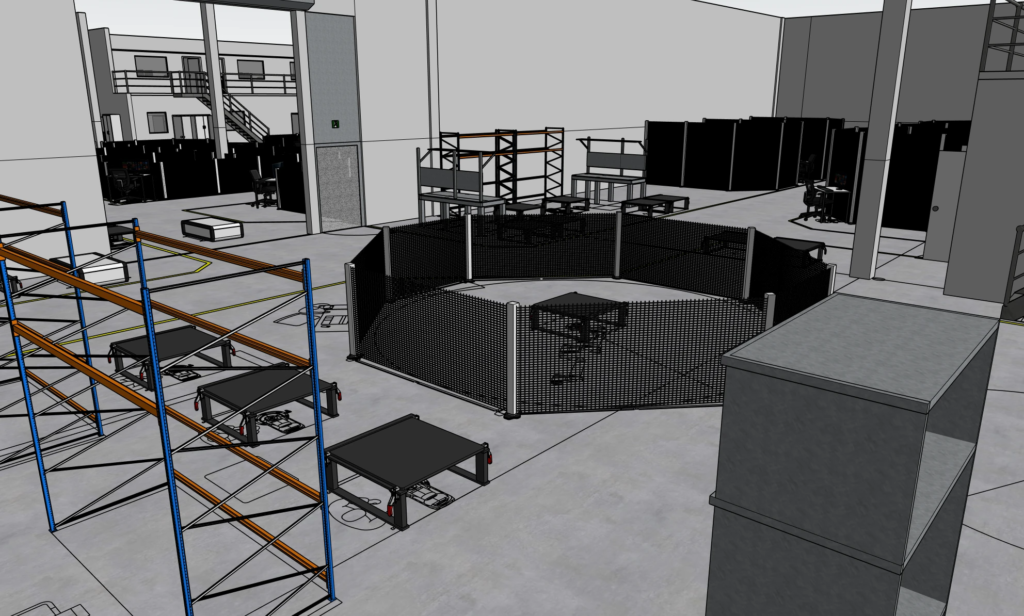

4. Layout Drafting (2D/3D)

Autodesk CAD, Revit, SketchUp visuals.

5. Workflow Simulation

Identifying bottlenecks before finalizing.

6. Final Layout Approval

Multiple revisions with the client.

7. On-site Implementation

Engineering support during layout execution.

Industrial Layout Trends for 2025

Lean manufacturing layouts

Automation-friendly layouts

Robotics integration

Digital twins

Energy-efficient facility planning

Hybrid industrial zones

Smart ventilation & workflow systems

Frequently Asked Questions (FAQs)

1. Why is industrial layout important?

It increases production speed, lowers cost, and ensures a smooth workflow.

2. Which industries need layout design?

Textile, food, pharma, auto parts, engineering, packaging, sports goods, and warehouses.

3. How much time does layout planning take?

Typically 2–6 weeks depending on complexity.

4. Does ACCO Engineering provide full design-build services?

Yes, from planning to PEB structures, civil, and MEP execution.

5. Can old factories be redesigned?

Absolutely. ACCO Engineering specializes in upgrading outdated layouts.

Internal Links (Add During Publishing)

External Links

Pakistan Engineering Council (pec.org.pk)

ArchDaily (archdaily.com)

OSHA Guidelines (osha.gov)

Government of Pakistan Construction Portal (construction.gov.pk)

Final Verdict

A perfect industrial layout is not just a design—it is a strategic investment that directly improves production output, workflow, and factory profitability.

ACCO Engineering offers proven, high-performance industrial layout designs that enhance:

Productivity

Space utilization

Safety

Material flow

Future expansion

Whether you’re establishing a new factory or upgrading an existing one, ACCO Engineering ensures a highly efficient, internationally aligned layout design tailored to your industry needs.

Call to Action (CTA)

📞 Contact ACCO Engineering today for a free industrial layout consultation!

🌐 Website: accoengineering.com

📱 WhatsApp: 0322-8000190

✉️ Email: info@acco.com.pk

Related Posts

Textile Factory PEB Buildings in Faisalabad | ACCO Engineering

Cost-Effective Pre-Engineered Buildings in Karachi | ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.