Steel & Pre-Engineered Building Specialists in Pakistan | ACCO Engineering

Introduction to ACCO Engineering – Trusted Construction Experts in Pakistan

ACCO Engineering is a leading name in Pakistan’s modern construction industry, recognized for delivering high-quality steel structures and pre-engineered buildings (PEB) across industrial, commercial, and institutional sectors. With years of hands-on experience, a skilled engineering team, and a commitment to international standards, ACCO Engineering has successfully completed projects across Lahore, Karachi, Islamabad, Faisalabad, Multan, and other major cities.

As part of the ACCO Group, our expertise covers:

Steel structure design & fabrication

Pre-engineered buildings (PEB)

Industrial sheds & warehouses

Factory buildings & workshops

Commercial steel structures

Turnkey construction solutions

Our mission is simple: deliver faster, stronger, and more economical construction solutions for Pakistan’s growing infrastructure and industrial needs.

Topic Introduction: Steel & Pre-Engineered Building Specialists in Pakistan

The demand for steel structures and pre-engineered buildings in Pakistan has increased rapidly due to rising construction costs, tight project timelines, and the need for durable, earthquake-resistant buildings.

Steel & Pre-Engineered Buildings (PEB) are factory-fabricated structures that are designed, engineered, and manufactured under controlled conditions and then assembled on-site. This construction method is transforming Pakistan’s:

Industrial sector

Logistics & warehousing

Manufacturing units

Commercial plazas

Sports complexes

Cold storage & agricultural facilities

With Pakistan moving toward industrialization, CPEC-linked development, and export-oriented manufacturing, PEB construction has become a strategic necessity rather than a luxury.

What Are Steel & Pre-Engineered Buildings (PEB)?

Definition of Pre-Engineered Buildings

A Pre-Engineered Building (PEB) is a steel structure that is designed using advanced engineering software, fabricated in factories, and then transported to the site for quick erection.

Key Components of PEB Structures

Primary framing: Columns & rafters

Secondary members: Purlins, girts, bracings

Roofing & wall sheets: Color-coated GI sheets

Insulation systems: Thermal & acoustic

Accessories: Skylights, ventilators, doors, gutters

Why Steel & PEB Construction Is Important in Pakistan

1. Rising Construction Costs

Traditional RCC construction is becoming increasingly expensive due to:

Cement price hikes

Steel bar price volatility

Labor shortages

PEB construction reduces overall costs by 15–30%.

2. Faster Project Delivery

Conventional construction: 12–18 months

PEB construction: 3–6 months

This speed is critical for factories, warehouses, and investors.

3. Seismic Safety

Pakistan lies in an earthquake-prone zone. Steel structures provide:

Higher ductility

Better energy absorption

Reduced collapse risk

4. Sustainability & Green Construction

Steel is:

100% recyclable

Environment-friendly

Energy-efficient when insulated properly

ACCO Engineering’s Steel & PEB Construction Services

1. Industrial Steel Buildings

Manufacturing plants

Textile mills

Engineering workshops

Assembly lines

2. Warehouses & Logistic Centers

Distribution warehouses

Cold storage facilities

FMCG storage units

E-commerce fulfillment centers

3. Commercial Steel Structures

Steel commercial plazas

Showrooms

Exhibition halls

Office buildings

4. Agricultural & Farm Structures

Poultry sheds

Dairy farm buildings

Grain storage units

5. Sports & Recreational Buildings

Indoor sports halls

Badminton & futsal courts

Gymnasiums

Steel Structure Construction Process at ACCO Engineering

Step 1: Requirement Analysis

Client needs

Site conditions

Load requirements

Budget planning

Step 2: Structural Design & Engineering

STAAD / ETABS analysis

Wind & seismic load calculations

Optimization for cost efficiency

Step 3: Fabrication

Factory-controlled fabrication

CNC cutting & welding

Quality inspections

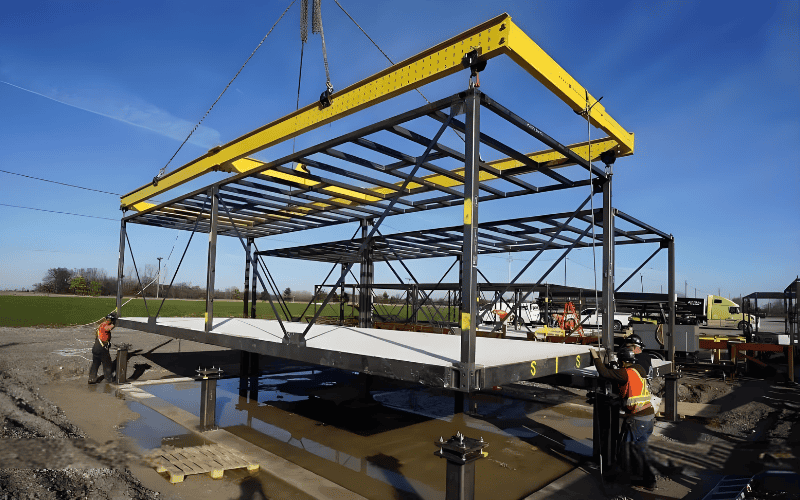

Step 4: Transportation & Erection

On-site assembly

Bolted connections

Crane-based erection

Step 5: Finishing & Handover

Roofing & cladding

Insulation installation

Final inspection

Comparison: PEB vs Conventional RCC Construction

| Feature | PEB Construction | RCC Construction |

|---|---|---|

| Construction Time | Very Fast | Slow |

| Cost | Economical | Expensive |

| Earthquake Resistance | High | Medium |

| Design Flexibility | Excellent | Limited |

| Maintenance | Low | High |

| Expandability | Easy | Difficult |

Advantages of Steel & Pre-Engineered Buildings

✅ Pros

🚀 Faster construction

💰 Lower overall cost

🏗️ High structural strength

🌍 Environment-friendly

🔧 Low maintenance

📐 Flexible & expandable designs

Disadvantages of Steel & PEB Construction

⚠️ Cons

❌ Requires skilled engineers

❌ Poor contractors may compromise quality

❌ Initial planning must be accurate

❌ Improper insulation can increase heat

👉 These disadvantages are easily controlled by choosing an experienced PEB specialist like ACCO Engineering.

Current Trends in Steel & PEB Buildings in Pakistan (2025–2026)

Increased use of thermal insulation panels

Adoption of solar-ready roofing systems

Export-oriented factory construction

Growth of logistics warehouses

Smart ventilation & daylight systems

According to industry reports and DAWN News, Pakistan’s industrial construction sector is shifting rapidly toward steel buildings due to efficiency and cost savings.

Frequently Asked Questions (FAQs)

1. What is the average cost of PEB construction in Pakistan?

The cost typically ranges from PKR 6,500 to PKR 12,000 per sq.ft, depending on design, loads, and specifications.

2. Are steel buildings safe in earthquakes?

Yes. Steel structures perform significantly better in earthquakes due to flexibility and ductility.

3. How long does a PEB project take?

Most projects are completed within 3–6 months, including design, fabrication, and erection.

4. Can PEB buildings be expanded later?

Absolutely. One of the biggest advantages of PEB is easy future expansion.

5. Does ACCO Engineering provide turnkey solutions?

Yes. ACCO Engineering offers complete turnkey PEB solutions from design to handover.

Internal Links (Suggested for SEO)

House Construction in DHA Lahore

Commercial Plaza Builders Lahore

Industrial Construction Services in Pakistan

Turnkey Construction Solutions by ACCO

External Authority References

Pakistan Engineering Council (PEC)

Construction guidelines by construction.gov.pk

Industry insights from DAWN News

Global steel design references from ArchDaily

(External links should be added contextually in the published version to improve trust and SEO.)

Image Suggestions with Alt Text

Alt text: “Pre-engineered steel warehouse construction in Pakistan”

Alt text: “Industrial steel structure building by ACCO Engineering”

Alt text: “PEB shed erection process in Lahore Pakistan”

Final Verdict: Why Choose ACCO Engineering for Steel & PEB Projects?

If you are planning an industrial, commercial, or warehouse project in Pakistan, steel & pre-engineered buildings are the smartest, fastest, and most economical solution.

With proven expertise, modern engineering tools, and a strong construction team, ACCO Engineering stands out as a trusted PEB specialist in Pakistan. Our focus on quality, safety, and timely delivery ensures long-term value for investors and businesses.

Call to Action – Let’s Build Smarter

📞 Contact ACCO Engineering today for a FREE consultation!

📲 Call / WhatsApp: 0322-8000190

🌐 Website: www.accoengineering.com

📧 Email: info@accoengineering.com

👉 Turn your construction vision into a durable steel reality with ACCO Engineering.

Related Posts

PEB Industrial Projects in Islamabad & Rawalpindi – ACCO Engineering

Warehouse & Factory Steel Buildings in Islamabad | ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.