Pre-Engineered Steel Structures in Islamabad | ACCO Engineering Experts

🏢 Introduction to ACCO Engineering

ACCO Engineering, a division of ACCO Construction, stands among Pakistan’s leading companies specializing in Pre-Engineered Steel Structures (PEB), industrial sheds, and customized metal buildings. Based in Lahore, with projects across Islamabad, Karachi, Multan, Faisalabad, and Gwadar, ACCO has built a strong reputation for engineering excellence, quality, and innovation.

With years of experience in steel fabrication, design-build construction, and industrial project management, ACCO provides turnkey PEB solutions for factories, warehouses, showrooms, sports halls, and logistics hubs.

At ACCO Engineering, every project is executed under strict quality control, ensuring strength, precision, and cost-efficiency — from concept to completion.

🌐 Visit www.acco.com.pk to explore our latest PEB projects and services.

🧱 Topic Introduction: Pre-Engineered Steel Structures in Islamabad

The capital city, Islamabad, is rapidly expanding with industrial zones, logistics hubs, and modern commercial facilities. In this fast-paced growth, Pre-Engineered Steel Structures (PEB) have become the preferred choice for construction due to their speed, durability, and cost-effectiveness.

Unlike conventional buildings that require months of onsite work, PEB structures are designed, fabricated, and assembled off-site — saving up to 40% of time and 30% of cost.

In Pakistan, especially in Islamabad’s industrial sectors (I-9, I-10, Kahuta, and Chakri), PEB buildings are being used for:

Warehouses 🏭

Factories ⚙️

Cold storage facilities ❄️

Exhibition halls 🎪

Aircraft hangars ✈️

Sports complexes 🏋️

ACCO Engineering’s expertise in PEB design and fabrication ensures every structure is engineered for strength, safety, and long-term reliability — tailored to Islamabad’s environment and local construction standards.

🏗️ What Are Pre-Engineered Steel Structures (PEB)?

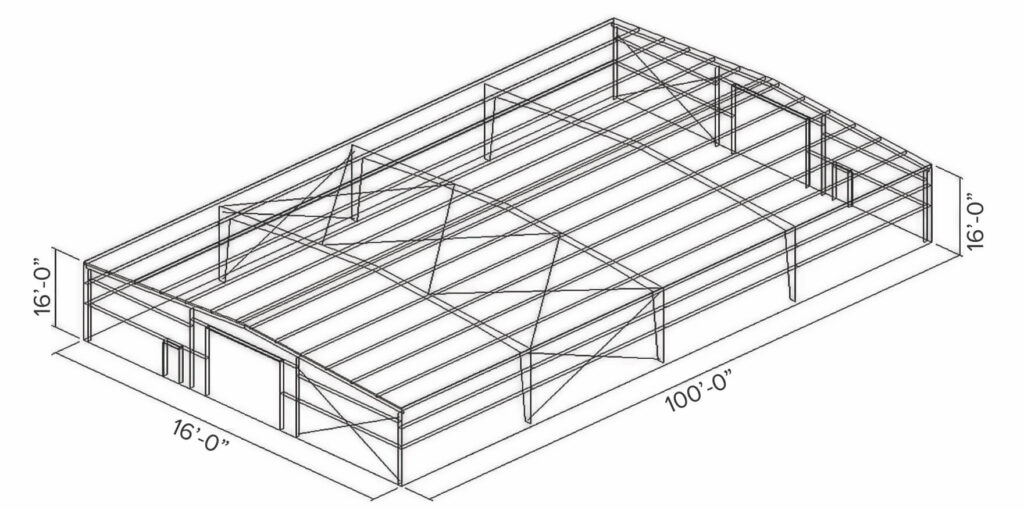

Pre-Engineered Steel Structures are buildings made of custom-designed steel frames manufactured in a factory and assembled on-site.

A typical PEB consists of:

Primary Frames: Rigid steel columns and rafters

Secondary Members: Purlins, girts, and eave struts

Roof & Wall Panels: Corrugated steel or insulated sandwich panels

Accessories: Skylights, ventilators, doors, and insulation

🔩 Key Advantages of PEB Systems

Reduced Construction Time – Fabrication and assembly happen simultaneously.

Cost-Effective – Optimized design reduces steel quantity and labor costs.

High Strength-to-Weight Ratio – Durable yet lightweight structures.

Low Maintenance – Corrosion-resistant coatings and minimal upkeep.

Eco-Friendly – Recyclable steel and energy-efficient roofing systems.

📊 The PEB Construction Process by ACCO Engineering

1. Project Consultation and Conceptual Design

Every project begins with a feasibility assessment, including:

Site layout and topography

Functional requirements (e.g., factory, warehouse, etc.)

Load and wind pressure analysis

Budgetary planning

Our team designs 3D models using Tekla Structures and STAAD Pro, providing detailed shop drawings and cost estimates.

2. Engineering and Fabrication

After design approval, steel components are fabricated in ACCO’s advanced workshops equipped with:

CNC cutting and drilling machines

Automatic welding systems

Surface treatment and painting booths

All materials meet ASTM and AISC standards, ensuring structural integrity and precision.

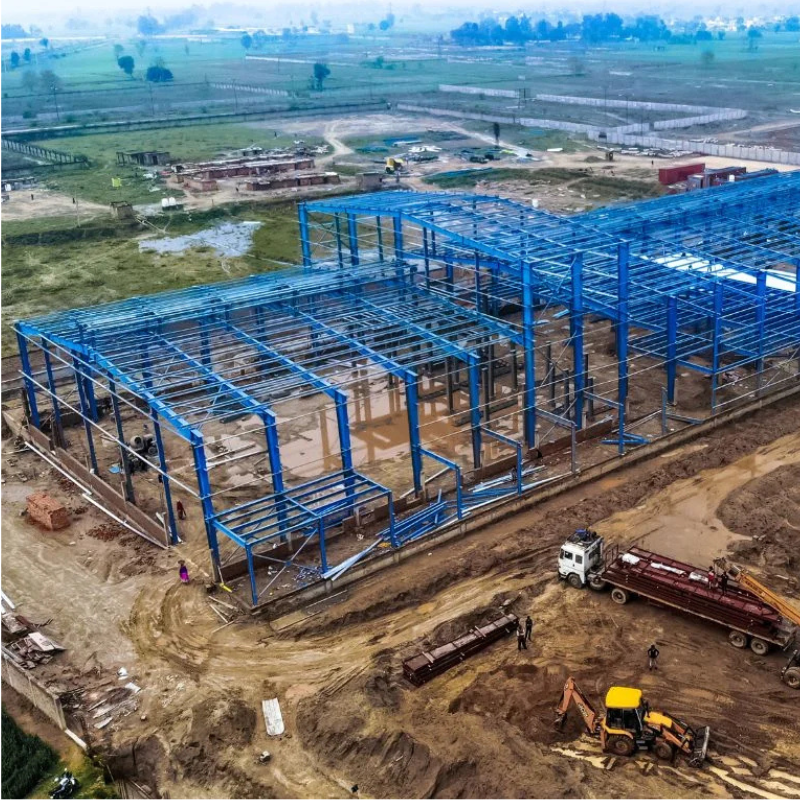

3. Delivery and Erection

Fabricated components are transported to the project site, where our skilled erection teams handle:

Foundation anchoring

Frame assembly

Roof & wall cladding

Insulation and finishing

ACCO follows strict safety and quality protocols, ensuring each joint, weld, and panel is executed flawlessly.

4. Finishing and Handover

After structural completion, we provide:

Interior partitioning (optional)

Electrical and plumbing integration

Skylights, louvers, and ventilators

Final inspection and warranty handover

Each project is delivered ready for use, with a 25-year structural guarantee and 5-year construction warranty.

🏢 Applications of PEB Buildings in Islamabad

| Sector | Usage | Benefits |

|---|---|---|

| Industrial | Factories, Workshops | Faster setup, heavy-load capacity |

| Commercial | Showrooms, Retail Centers | Wide spans, aesthetic design |

| Agricultural | Storage, Dairy Farms | Weather-resistant, ventilated |

| Institutional | Schools, Auditoriums | Cost-saving, durable |

| Aviation | Hangars, Maintenance Bays | Large clear spans, flexible design |

| Logistics | Warehouses, Cold Storage | Efficient space utilization |

🌍 Why PEBs Are Ideal for Islamabad’s Climate

Islamabad’s environment demands energy-efficient, thermally stable, and durable structures.

PEB systems by ACCO offer:

Thermal insulation panels to withstand temperature fluctuations

High wind load capacity for storm resistance

Anti-corrosion coatings for long life

Water-tight roofing systems for monsoon protection

These qualities make PEBs the best solution for industrial and commercial expansion in Islamabad and Rawalpindi.

✅ Pros and Cons of Pre-Engineered Steel Structures

Advantages

⚙️ Quick Installation – Reduces project duration by up to 50%.

💰 Cost Efficiency – Lower construction and maintenance costs.

🏭 Design Flexibility – Custom sizes and architectural aesthetics.

🌎 Sustainability – Steel is 100% recyclable.

🔧 Durability – Withstands harsh environments and seismic activity.

Disadvantages

💡 High Initial Planning Requirement – Needs detailed engineering upfront.

🔋 Thermal Conductivity – Requires insulation for temperature control.

🔩 Transportation Limitations – Large members need proper logistics planning.

📈 Market Trends in PEB Construction (2025 Outlook)

Pakistan’s PEB market is projected to grow by 15–18% annually (Source: DAWN Business Review).

Increased demand in CPEC industrial zones and defense infrastructure.

Rising trend of green steel buildings and solar-integrated PEB roofs.

Shift toward hybrid PEB-concrete structures for commercial complexes.

ACCO Engineering remains at the forefront of this growth by offering turnkey PEB solutions with complete design, fabrication, and erection capabilities.

💬 Frequently Asked Questions (FAQs)

1. What is the typical lifespan of a pre-engineered steel building?

A well-maintained PEB can last over 50 years, depending on coatings and environmental factors.

2. Are PEB buildings suitable for seismic zones like Islamabad?

Yes. ACCO designs structures to seismic zone 3 standards, ensuring safety and stability.

3. How long does it take to construct a PEB warehouse?

Depending on size, a warehouse can be completed within 60 to 120 days.

4. Can ACCO handle both design and construction?

Yes. ACCO provides complete design-build services, managing every phase from concept to completion.

5. What type of maintenance do steel buildings require?

Only periodic inspections and repainting every 10–15 years for corrosion protection.

🔗 Related Internal Links

🌐 External References

🏁 Final Verdict

Pre-Engineered Steel Structures are revolutionizing the way Islamabad builds its industries and commercial spaces. They combine speed, strength, and sustainability — offering a modern alternative to traditional concrete buildings.

With unmatched experience and technical expertise, ACCO Engineering continues to lead the PEB revolution in Pakistan. Whether it’s an industrial shed, logistics warehouse, or commercial hall, we deliver world-class steel structures that meet global standards.

📞 Call to Action

🚀 Contact ACCO Engineering today for a free consultation and quotation!

📍 Office: 2nd Floor, BigCity Plaza, Gulberg-III, Lahore

📧 Email: info@acco.com.pk

📞 Phone/WhatsApp: 0322-8000190

🌐 Visit: www.acco.com.pk

Related Posts

PEB Industrial Projects in Islamabad & Rawalpindi – ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.