A–Z Guide to Steel PEB Shed Manufacturing in Pakistan

By ACCO Engineering

⭐ Introduction to ACCO Engineering

ACCO Engineering is one of Pakistan’s most trusted names in Pre-Engineered Buildings (PEB), industrial steel structures, sports & leisure solutions, and large-scale metal fabrication services.

Based in Lahore, ACCO Engineering has delivered hundreds of industrial PEB sheds, warehouses, factories, cold storage units, logistics centers, and mega steel structures across Pakistan.

Our expertise covers:

-

Steel PEB Shed Manufacturing

-

Industrial Layout Planning

-

Turnkey Industrial Construction

-

Structural Engineering

-

PEB Design, Fabrication & Installation

If you want a high-performance PEB building that improves production efficiency, reduces cost, and speeds up industrial operations, ACCO Engineering provides end-to-end turnkey solutions.

🏗️ A–Z Guide to Steel PEB Shed Manufacturing in Pakistan

Pakistan’s industrial sector is transforming rapidly — and Pre-Engineered Buildings (PEB) are now the backbone of modern factories, warehouses, manufacturing units, and agro-industrial setups.

This A–Z guide covers everything you need to know about steel PEB shed manufacturing, from planning and design to fabrication, erection, quality control, and final commissioning.

And most importantly, you’ll understand how PEB buildings boost industrial efficiency, which is our article’s main focus.

🔤 A — Assessment of Client Needs

The PEB process begins with a detailed requirement assessment:

-

What industry sector? Textile, FMCG, Pharma, Auto, Cold Storage?

-

Required size (length, width, height)

-

Crane load requirements

-

Maximum storage or production output

-

Ventilation & insulation needs

-

Future expansion requirements

This assessment helps engineers propose a structure that matches operational needs and supports maximum productivity.

🔤 B — Budget Planning & Bill of Quantities (BOQ)

A BOQ includes:

-

Steel weight estimation

-

Fabrication cost

-

Installation cost

-

Foundation & civil works

-

Accessories (ventilators, skylights, insulation, gutter system)

PEB systems are 30–40% more cost-efficient than conventional RCC construction — making them ideal for new factories in 2025.

🔤 C — Conceptual Design

At this stage, ACCO Engineering prepares:

-

2D/3D conceptual drawings

-

Structural framing layout

-

Column grid design

-

Clearance height optimization

-

Bay spacing

-

Load calculations

-

Architectural elevations

Concept design ensures your shed is both functionally efficient and aesthetically modern.

🔤 D — Detailed Engineering

This includes:

-

Structural analysis using advanced software

-

Wind loads, dead loads, live loads

-

Frame optimization

-

Weld size design

-

Steel section selection

-

Foundation load calculation

This is where PEB engineering ensures the structure is strong, durable, and compliant with international standards.

🔤 E — Estimation & Steel Weight Calculation

Steel weight directly impacts cost.

Accurate weight calculation = transparent pricing.

ACCO Engineering provides:

-

Weight breakdown per component

-

Material specification list

-

Material grade (Galvanized / ASTM / A36 / A572)

🔤 F — Fabrication

Fabrication is the heart of PEB manufacturing.

It includes:

-

CNC plasma cutting

-

Automatic welding

-

Beam welding

-

Drilling

-

Sand blasting

-

Galvanization or paint coating

-

Quality inspection

ACCO Engineering uses international-grade automated machinery to ensure precision and durability.

🔤 G — Galvanization & Surface Treatment

Protection against corrosion includes:

-

Hot-dip galvanization

-

Epoxy coating

-

Zinc-rich primers

-

Weather-resistant paint

This guarantees long lifespan even in harsh climates.

🔤 H — Handling & Transport

Steel members are transported carefully using:

-

Protective wrapping

-

Non-destructive loading

-

Secure fastening

-

Tiered stacking

Proper handling ensures the material reaches the site damage-free.

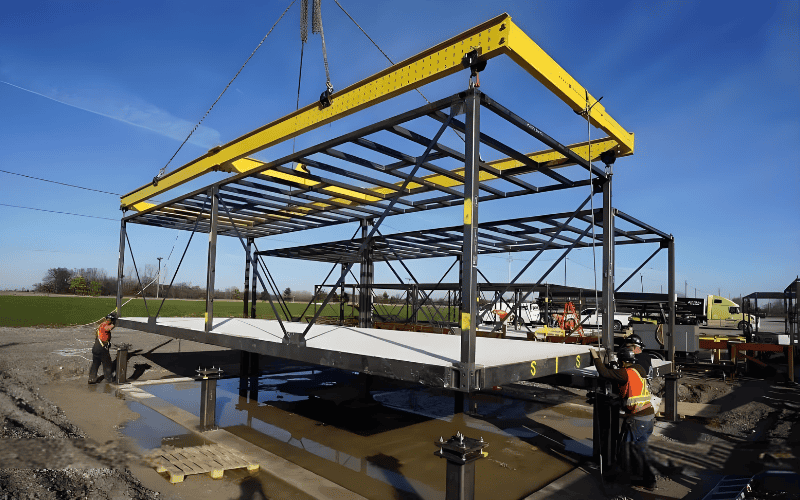

🔤 I — Installation & Erection

On-site erection includes:

-

Anchor bolt alignment

-

Column installation

-

Rafters & girts

-

Sheeting installation

-

Insulation

-

Fasteners placement

-

Ridge vents & skylights

PEB erection is fast, usually 45–60% quicker than conventional methods.

🔤 J — Joint Inspection

Both client and engineering team verify:

-

Structural alignment

-

Bolt torque

-

Welding quality

-

Sheeting finishing

-

Insulation quality

-

Accessory installation

This ensures everything matches drawings and standards.

🔤 K — Key Performance Indicators (KPIs)

Performance is evaluated using:

-

Production output

-

Energy efficiency

-

Temperature control

-

Workflow movement

-

Safety compliance

PEB buildings enhance these KPIs significantly.

🔤 L — Lifecycle Cost Savings

PEB = long-term savings:

-

Low maintenance

-

High energy efficiency

-

Easy expansion

-

Zero structural repairs

-

Long life (50+ years)

🔤 M — Material Standards

High-quality steel ensures superior performance:

-

ASTM A36

-

A572 Grade 50

-

Galvanized GI sheets

-

PUF panels

-

Polycarbonate skylights

🔤 N — Noise Reduction & Insulation

Industries require proper insulation to improve worker comfort and energy efficiency.

Options include:

-

Glass wool

-

Rockwool

-

PU insulation panels

🔤 O — Operational Efficiency Boost (Main Keyword Integration)

How PEB Buildings Improve Industrial Efficiency

Using our main focus keyword, here’s the value:

PEB Buildings for Industrial Efficiency improve:

-

Production workflow

-

Material handling

-

Storage capacity

-

Energy savings

-

Machinery movement

-

Safety & temperature control

This is exactly why factories in 2025 are shifting from RCC to PEB.

🔤 P — Project Management

ACCO Engineering ensures:

-

Daily progress reports

-

Strict timelines

-

Quality control

-

Safety checks

🔤 Q — Quality Assurance

We follow:

-

ISO standards

-

Welding tests

-

Steel grade tests

-

Load tests

-

Structural level checks

🔤 R — Risk Management

Includes:

-

Fire safety planning

-

Emergency exits

-

Load safety design

-

Wind-resistant frame design

🔤 S — Site Planning

Efficient site layout improves:

-

Production flow

-

Loading/unloading

-

Waste management

-

Employee movement

🔤 T — Turnkey Solutions

ACCO Engineering offers complete A to Z turnkey PEB delivery including:

-

Layout

-

Drawings

-

Fabrication

-

Installation

-

Civil works

🔤 U — Utility Planning

Includes:

-

Electrical wiring plan

-

Lighting layout

-

HVAC ducting

-

Drainage & gutter systems

🔤 V — Ventilation Design

Proper ventilation maintains temperature & reduces energy load.

Options:

-

Ridge vents

-

Turbo ventilators

-

Louvers

-

Sky vents

🔤 W — Warehouse Planning

A well-designed warehouse includes:

-

Racking planning

-

Forklift movement space

-

Loading bays

-

Mezzanine floors

🔤 X — X-Factor: Speed

The biggest advantage of PEB?

Speed.

PEB sheds are completed 60% faster, allowing industries to start operations early.

🔤 Y — Yield Optimization

PEB structures improve:

-

Storage output

-

Production workflow

-

Machinery safety

-

Energy efficiency

🔤 Z — Zero Maintenance

PEB buildings require almost no maintenance, making them ideal for long-term industrial operations.

📌 Conclusion

Steel PEB shed manufacturing is now the future of industrial construction in Pakistan. ACCO Engineering brings international PEB standards with advanced engineering, fast installation, and superior efficiency — ensuring industries work faster, safer, and more profitably.

📞 Contact ACCO Engineering

📍 Website: www.accoengineering.com

📧 Email: info@accoengineering.com

Related Posts

PEB Industrial Projects in Islamabad & Rawalpindi – ACCO Engineering

Steel & Pre-Engineered Building Specialists in Pakistan | ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.