Durable PEB Construction in Faisalabad – ACCO Engineering

🏢 Introduction to ACCO Engineering

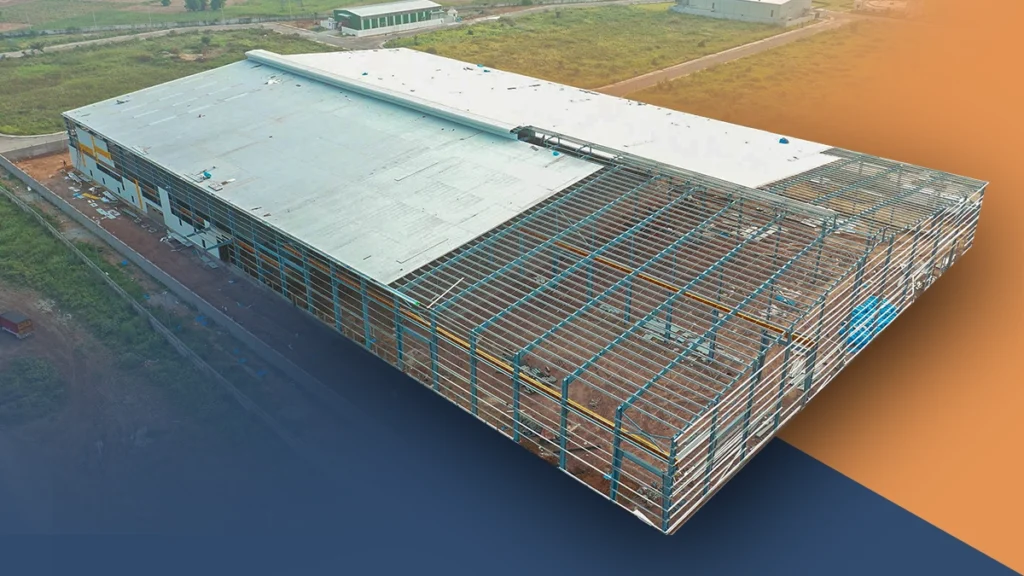

ACCO Engineering is one of Pakistan’s most trusted and experienced construction and engineering firms, specializing in Pre-Engineered Buildings (PEB), industrial steel structures, and turnkey construction projects.

Located in Lahore, Pakistan, ACCO Engineering proudly serves clients across major industrial cities including Faisalabad, Karachi, Islamabad, Multan, and Gujranwala.

With decades of combined experience, ACCO Engineering is known for delivering durable, cost-effective, and time-efficient PEB solutions tailored to the local climate and industrial needs. Our expertise includes:

🏗️ Industrial PEB Buildings

🏭 Warehouses & Factories

🏬 Cold Storage Units

🏢 Commercial Steel Buildings

🏠 Prefabricated Residential Structures

Visit: www.acco.com.pk

🌆 Topic Introduction: Durable PEB Construction in Faisalabad

Faisalabad — known as the “Manchester of Pakistan” — is one of the country’s largest industrial hubs. With continuous growth in textiles, manufacturing, and logistics, the demand for durable and fast-track construction has increased dramatically.

This is where Pre-Engineered Buildings (PEBs) play a key role. PEB construction allows industries to build strong, scalable, and cost-efficient facilities in record time — making it a preferred choice for factories, warehouses, and industrial parks in Faisalabad.

ACCO Engineering leads the PEB sector in Faisalabad by combining modern engineering techniques with locally optimized designs, ensuring long-term performance, low maintenance, and structural integrity.

🔍 Understanding PEB Construction

What is PEB Construction?

Pre-Engineered Building (PEB) construction involves designing and fabricating structural components (like beams, columns, and panels) off-site in a controlled environment. These are then transported and assembled on-site, drastically reducing construction time and errors.

Key Components of PEB Structures

Primary Frame: Main steel members (columns, rafters, girders).

Secondary Members: Purlins, girts, eave struts for additional support.

Roof & Wall Panels: Insulated or single-skin panels for protection and aesthetics.

Accessories: Ventilators, skylights, louvers, gutters, and trims.

Foundation: Simple and cost-effective since PEBs are lightweight.

⚙️ Why PEB Construction is Growing in Faisalabad

1. Rapid Industrial Growth

Faisalabad’s industrial zones — like M3 Industrial City and Allama Iqbal Industrial Estate — require large warehouses and manufacturing units. PEBs are ideal for quick deployment and expansion.

2. Cost-Efficiency

PEBs can reduce overall construction costs by up to 30%, thanks to optimized steel usage and faster assembly time.

3. Energy Efficiency

Modern PEBs are designed for thermal insulation, natural ventilation, and light optimization — perfect for the warm climate of Faisalabad.

4. Design Flexibility

PEBs support large clear spans (up to 90m) without intermediate columns — ideal for storage, textile production, and machinery setups.

5. Sustainability

Steel structures are eco-friendly and 100% recyclable, aligning with Pakistan’s green building vision.

🧱 Durable Construction Methods Used by ACCO Engineering

At ACCO Engineering, durability is our hallmark. We follow advanced design and material standards to ensure structural strength even under harsh weather or industrial loads.

Our Durability Enhancement Methods:

Hot-dip galvanized steel to prevent corrosion

High-tensile bolted connections for longer life

Weather-resistant roofing systems

Load-tested primary frames compliant with ASTM & AISC codes

Powder-coated finishes for enhanced aesthetic life

Material Standards:

| Component | Material Grade | Standard |

|---|---|---|

| Main Frames | ASTM A572 Grade 50 | AISC Certified |

| Roof Panels | AZ150 Galvanized Steel | ISO 9001 |

| Bolts & Nuts | Grade 8.8 / 10.9 | DIN Standards |

| Insulation | Glass Wool / PU Panels | EN Certified |

🏭 Applications of PEB in Faisalabad

PEB systems can be used across various sectors in Faisalabad’s growing economy:

Textile & Garment Factories 👕

Logistics & Distribution Centers 🚛

Cold Storage & Food Processing Units ❄️

Commercial Showrooms & Workshops 🏢

Educational & Healthcare Facilities 🏫

Warehousing & Storage Buildings 📦

Agricultural Structures & Sheds 🌾

💡 Advantages of PEB Construction

✅ Pros of PEB Construction

Fast Construction: 50% quicker than traditional methods.

Cost-Effective: Reduced labor, waste, and timeline.

Durable: Resistant to corrosion, fire, and seismic activity.

Flexible: Easy expansion and modification options.

Eco-Friendly: Reusable and recyclable steel materials.

Low Maintenance: Long service life with minimal upkeep.

Energy Efficient: Better insulation and ventilation systems.

⚠️ Cons of PEB Construction

High Initial Design Cost: Requires professional engineering input.

Limited Aesthetic Options: Customization may increase costs.

Skilled Installation Required: Needs trained assembly teams.

Transport Limitations: Large components need logistic planning.

📈 Comparison: PEB vs Traditional Construction

| Feature | PEB Construction | Traditional RCC |

|---|---|---|

| Construction Speed | 3–6 Months | 12–18 Months |

| Cost Efficiency | 20–30% Cheaper | Expensive |

| Flexibility | Easy to Expand | Difficult |

| Strength | High Tensile Steel | Moderate |

| Maintenance | Low | High |

| Sustainability | Recyclable Steel | Concrete Waste |

🌍 PEB Market Trends in Pakistan

According to Pakistan Engineering Council (PEC) and DAWN Business Reports, the demand for pre-engineered structures has grown over 40% in the last 5 years. Faisalabad, being an industrial hub, contributes significantly to this trend.

Future projections (2025–2030):

Increase in automated PEB fabrication plants

Focus on energy-efficient industrial facilities

Integration of smart sensors and IoT for maintenance

❓ Frequently Asked Questions (FAQs)

1. What is the lifespan of a PEB building?

A well-maintained PEB can last 40–60 years, depending on material quality and environment.

2. How much time does it take to construct a PEB in Faisalabad?

A standard industrial PEB (around 20,000 sq. ft.) can be completed within 3–5 months.

3. Are PEB buildings safe during earthquakes?

Yes, they are designed according to seismic zone codes of Pakistan, ensuring superior safety.

4. Can PEBs be customized for my factory or warehouse design?

Absolutely! ACCO Engineering offers customized layouts tailored to client requirements.

5. What is the cost per square foot for PEB in Faisalabad?

Depending on specifications, the cost ranges between PKR 1,800 – 2,800 per sq. ft. (including structure and basic civil works).

🏁 Final Verdict / Conclusion

Durable PEB Construction in Faisalabad represents the future of Pakistan’s industrial infrastructure. With speed, strength, and sustainability, it empowers industries to expand efficiently.

As Faisalabad continues its journey toward modernization, ACCO Engineering stands as the trusted partner for durable, affordable, and high-quality PEB solutions.

Whether you need an industrial shed, textile factory, or warehouse, our team ensures precision and excellence from design to execution.

🔗 Internal Links

🌐 External Links

📞 Call to Action

Looking for Durable PEB Construction in Faisalabad?

👉 Contact ACCO Engineering today for a free consultation!

📧 Email: info@acco.com.pk

📞 Phone: 0322 8000190

🌐 Website: www.acco.com.pk

📍 Office: Office 2, 3rd Floor Big City Plaza, Gulberg-III, Lahore

Related Posts

PEB Industrial Projects in Islamabad & Rawalpindi – ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.