How PEB Saves 40% Construction Time — Complete Breakdown

Introduction to ACCO Engineering 🏢

ACCO Engineering is a leading construction and engineering company based in Lahore, specializing in Pre-Engineered Buildings (PEB), industrial sheds, commercial structures, and turnkey construction solutions across Pakistan.

With years of expertise and hundreds of completed projects, ACCO Engineering has become a trusted name for clients looking for efficient, durable, and modern construction solutions. Our team combines innovative engineering, precise fabrication, and project management excellence to deliver structures that meet both aesthetic and functional needs.

Our Specializations Include:

Pre-Engineered Buildings (PEB) for industrial and commercial use

Turnkey construction projects

Steel fabrication and installation

Design and build services for large-scale industrial facilities

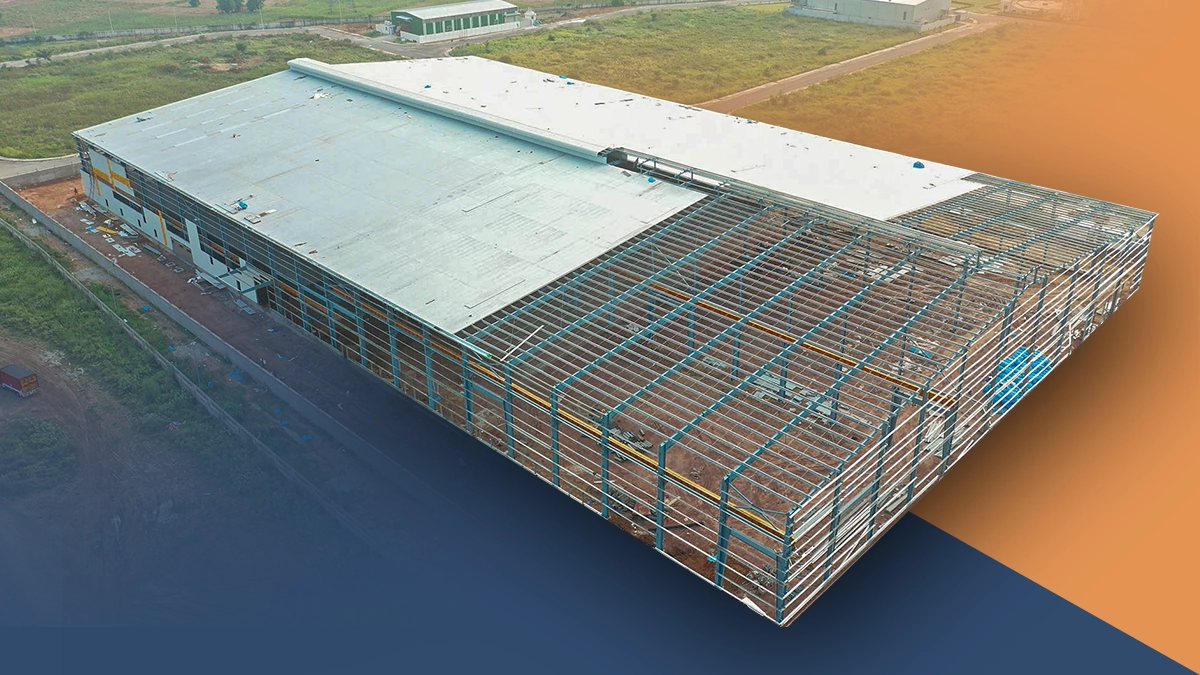

What Are Pre-Engineered Buildings (PEB)? 🏗️

A Pre-Engineered Building (PEB) is a modern construction system where structural components are designed and fabricated off-site, then assembled on-site. Unlike conventional brick-and-mortar buildings, PEBs rely on steel frameworks, modular panels, and advanced engineering, making them faster, more cost-effective, and durable.

Why PEB is Important in Pakistan:

Rapid industrialization and urban expansion in Lahore, Karachi, and Islamabad

High demand for factories, warehouses, and commercial facilities

Need for time-efficient and cost-effective construction methods

Growing trend of export-oriented industrial projects requiring durable steel structures

How PEB Reduces Construction Time by 40% ⏱️

1. Off-Site Fabrication

Components such as columns, beams, and roof panels are manufactured in controlled factory environments.

Precision and quality control are easier to maintain, reducing rework on-site.

Speeds up construction by 20–30%.

2. Modular Design for Quick Assembly

PEB structures are modular, meaning components fit together seamlessly.

Minimizes on-site labor hours and delays.

Ideal for industrial sheds, warehouses, and commercial projects.

3. Lightweight Steel Structures

Steel frames are lighter than concrete, reducing foundation requirements.

Accelerates site preparation and foundation work.

Supports large open spaces without internal columns.

4. Advanced Technology & CAD Integration 💻

All PEB components are designed using Computer-Aided Design (CAD) for high accuracy.

Reduces errors and ensures faster approvals and efficient material planning.

5. Fast Roofing & Cladding

Roof panels and wall cladding are pre-cut and pre-insulated.

Installation is significantly faster than traditional construction.

Time & Cost Comparison: PEB vs Conventional Construction 💰

| Feature | Conventional Building | PEB Building |

|---|---|---|

| Construction Time | 12–18 months | 7–10 months |

| Labor Requirement | High | Moderate |

| Material Waste | High | Low |

| Design Flexibility | Limited | High |

| Durability | Moderate | High |

PEB saves approximately 40% of construction time, while offering better durability and flexibility for large-scale projects.

Benefits of PEB Construction ✅

⚡ Faster Construction – Up to 40% time reduction

💸 Cost-Effective – Reduced labor, foundation, and material costs

🏗️ Flexible Design Options – For warehouses, factories, and offices

🌦️ Weather-Resistant – Less affected by rain, wind, or harsh conditions

🔧 Low Maintenance – Steel structures are durable and easy to maintain

Potential Limitations ❌

🏢 Less suitable for ultra-luxury residential projects

🔩 Requires skilled installation and certified engineers

🌍 Limited local suppliers in certain regions may affect lead times

Popular PEB Types in Pakistan 🇵🇰

Single-Story Industrial Sheds – Factories, warehouses, workshops

Multi-Story Commercial PEBs – Office buildings, retail spaces, showrooms

Cold Storage & Agro Facilities – Insulated panels for temperature-sensitive goods

Custom Turnkey PEB Projects – Full-service design, fabrication, and installation

Factors Affecting PEB Efficiency ⚙️

Design Accuracy: Proper CAD and engineering design reduces errors

Fabrication Quality: Factory precision ensures faster on-site assembly

Project Size & Complexity: Larger spans may require more time, but still faster than conventional methods

Local Regulations & Approvals: Efficient approvals help reduce project delays

FAQs About PEB Construction ❓

1. What is the lifespan of a PEB?

With proper maintenance, PEBs last 30–50 years, making them a long-term investment.

2. Can PEB withstand Pakistan’s weather?

Yes, modern PEBs are designed to resist heavy winds, rain, and seismic activity.

3. Is PEB more expensive than conventional construction?

While upfront costs may be slightly higher, faster construction and lower labor costs make it more economical overall.

4. How long does it take to construct a PEB warehouse?

7–10 months for medium-sized warehouses is typical, depending on size and customization.

5. Can I customize my PEB design?

Absolutely. PEBs allow flexible layouts, interior modifications, and façade designs.

Internal Links for ACCO Engineering 🔗

External References 🌐

Final Verdict / Conclusion 🏁

Pre-Engineered Buildings (PEB) are revolutionizing Pakistan’s construction sector. By reducing construction time by up to 40%, offering cost savings, design flexibility, and durability, PEB is the preferred choice for industrial, commercial, and large-scale projects.

For businesses and investors looking for efficient, reliable, and modern construction solutions, ACCO Engineering is your trusted partner.

📞 Contact ACCO Engineering today for a free consultation!

Phone: +92 300 2358853

WhatsApp: +92 311 1749849

Related Posts

Post a Comment cancel reply

You must be logged in to post a comment.