How to Plan a PEB Layout for Maximum Industrial Productivity | ACCO Engineering

Introduction to ACCO Engineering

ACCO Engineering is a premier engineering and construction company based in Lahore, Pakistan, specializing in industrial, commercial, and sports & leisure solutions. With over 10+ years of experience, ACCO Engineering has successfully delivered customized industrial facilities, pre-engineered buildings (PEBs), and turnkey projects for leading brands.

Our expertise lies in combining innovative design, structural integrity, and operational efficiency, making us a trusted partner for industries looking to maximize productivity and minimize costs.

Introduction to Planning a PEB Layout

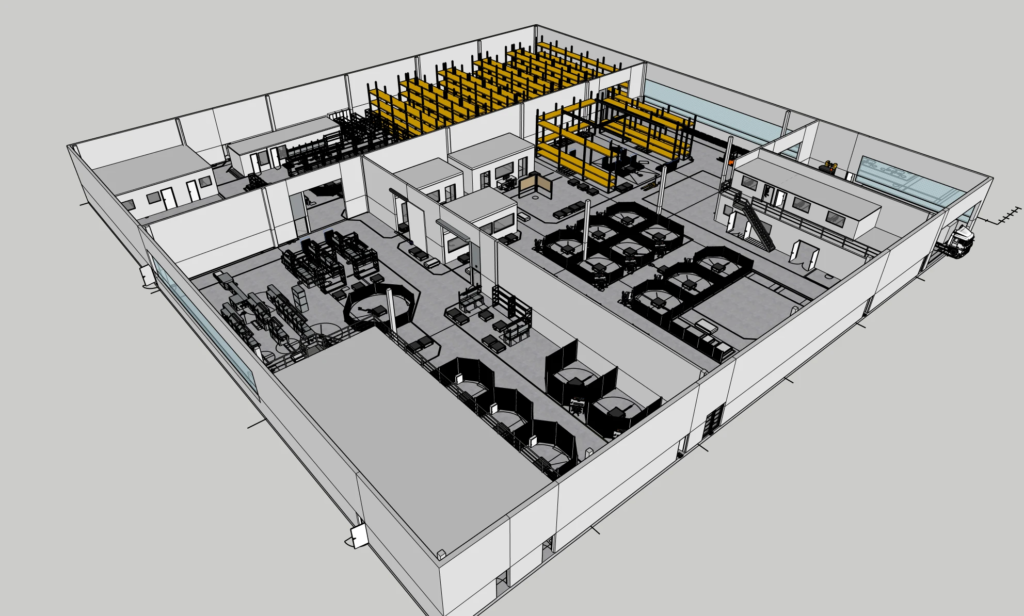

A Pre-Engineered Building (PEB) layout is the backbone of industrial efficiency. Proper planning ensures optimal workflow, reduces operational bottlenecks, and increases overall productivity.

In Pakistan, industries like textile, pharmaceutical, and FMCG are rapidly expanding. Efficient PEB layouts help businesses adapt to growing production demands, comply with safety regulations, and reduce operational costs.

By investing time in strategic PEB layout planning, companies can achieve a functional, scalable, and cost-effective industrial facility.

Key Considerations for Planning a PEB Layout

H2: Understanding Operational Workflow

Before designing the PEB, it is crucial to map out the operational process:

Identify core production areas

Define storage zones for raw materials and finished goods

Allocate loading and unloading bays

Plan office and administrative sections within the facility

A clear understanding of workflow ensures smooth material movement and minimal downtime.

H2: Space Optimization

Efficient use of space is critical for industrial productivity:

Column-free areas allow flexible placement of machinery

High-clearance roofs accommodate large equipment

Mezzanine floors provide additional storage or operational areas

Wide aisles facilitate forklift and worker movement

Proper space planning reduces congestion and improves safety.

H2: Safety and Compliance

PEB layouts must adhere to industry safety standards:

Fire exits and emergency routes clearly marked

Chemical storage areas designed with anti-corrosive materials

Electrical and plumbing systems planned to avoid hazards

Seismic-resistant structural design for earthquake-prone regions

Following these measures ensures employee safety and regulatory compliance.

H2: Material Handling and Logistics

Efficient material flow enhances productivity:

Loading/unloading bays near storage zones

Conveyor belts or automated systems for large-scale industries

Dedicated shipping and receiving areas

Clear signage and workflow maps

Proper logistics planning minimizes delays and reduces operational costs.

H2: Flexibility and Future Expansion

A well-planned PEB layout considers future growth:

Modular sections for easy expansion

Structural reinforcement to support additional equipment

Provisions for new production lines or storage areas

This approach allows industries to scale operations without major construction delays.

H2: Environmental and Energy Efficiency

Sustainable layouts save costs and comply with regulations:

Natural lighting reduces electricity consumption

Insulated walls and roofing maintain temperature control

Rainwater harvesting and drainage systems

Solar panels or energy-efficient HVAC systems

Green layouts enhance efficiency and promote environmental responsibility.

Pros and Cons of Planning a PEB Layout

✅ Pros:

Improves operational workflow

Reduces downtime and operational costs

Facilitates future expansion

Enhances employee safety

Supports energy efficiency initiatives

❌ Cons:

Requires upfront planning and investment

May need professional consultants for optimal design

Layout adjustments after construction are costly

Frequently Asked Questions (FAQs)

Q1: What is the importance of a PEB layout?

A: A PEB layout optimizes workflow, reduces operational costs, and enhances safety in industrial facilities.

Q2: How long does it take to design a PEB layout?

A: Depending on complexity, layout planning may take 2–4 weeks, including workflow analysis and structural design.

Q3: Can PEB layouts be modified after construction?

A: Modifications are possible but costly; it’s best to plan for future expansion during initial design.

Q4: Are PEB layouts suitable for textile and pharma industries?

A: Yes, they provide column-free spaces, high ceilings, and flexible zoning for machinery and production lines.

Q5: How does a PEB layout improve productivity?

A: By reducing material handling time, optimizing workflow, and ensuring smooth movement of goods and personnel.

Trends in PEB Layout Design in Pakistan

Smart automation integration for material handling

Hybrid layouts combining PEB and conventional structures

Seismic-resistant and anti-corrosive materials

Multi-story warehouses for maximum storage efficiency

Energy-efficient industrial layouts

Final Verdict / Conclusion

Proper PEB layout planning is critical for industries in Pakistan looking to maximize productivity and operational efficiency. ACCO Engineering provides custom turnkey solutions that combine structural integrity, operational efficiency, and future scalability.

Whether you operate in textile, pharmaceutical, or FMCG industries, a strategically planned PEB layout ensures:

Smooth workflow

Reduced operational costs

Safe and compliant facilities

Scalable infrastructure for future growth

Internal Links

External Links

Call to Action

📞 Contact ACCO Engineering today for a free consultation!

🌐 Website: www.accoengineering.com

📧 Email: info@acco.com.pk

WhatsApp: 0322-8000190

Related Posts

Modern Pre-Engineered Industrial Structures in Islamabad | ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.