PEB Construction in Lahore – Factory, Warehouse & Industrial Building Experts | ACCO Construction

🏢 Introduction to ACCO Construction

ACCO Construction is one of Pakistan’s leading names in the construction and engineering industry, recognized for its innovation, precision, and quality craftsmanship. Headquartered in Lahore, ACCO has delivered hundreds of successful projects nationwide, ranging from residential and commercial buildings to industrial and pre-engineered structures (PEBs).

With over 20 years of experience, ACCO Construction is known for its turnkey solutions, modern technologies, and commitment to excellence. Our in-house team of architects, engineers, and project managers ensures that every structure we build stands as a symbol of durability, efficiency, and modern design.

For industrial clients, our specialty lies in Pre-Engineered Steel Buildings (PEBs) — offering unmatched benefits in terms of cost, time, and sustainability.

⚙️ What Is PEB Construction?

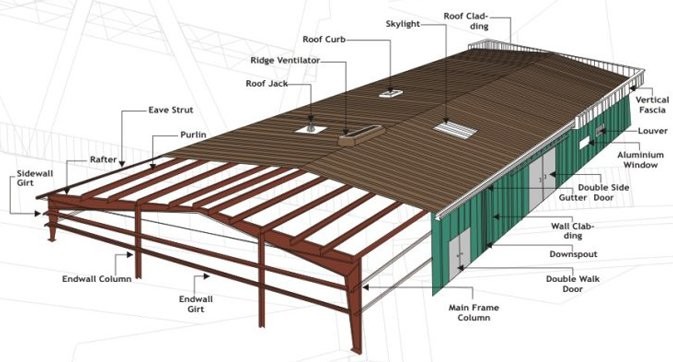

PEB (Pre-Engineered Building) construction refers to a modern method where building components — such as primary frames, roofing systems, and wall panels — are manufactured in a controlled factory environment and then transported to the construction site for assembly.

Unlike traditional RCC (Reinforced Cement Concrete) structures, PEBs are:

Faster to build

More cost-effective

Structurally reliable

Highly customizable

PEBs are widely used in factories, warehouses, cold storages, sports arenas, and workshops, especially in industrial hubs like Lahore, Faisalabad, and Karachi.

🇵🇰 Importance of PEB Construction in Lahore and Pakistan

With Lahore being a major industrial city, the demand for efficient, long-lasting, and economical buildings is growing rapidly. Businesses are now turning to PEB construction for their industrial and commercial projects.

Why PEBs Are the Future of Construction in Pakistan:

⚡ Fast Project Completion: Up to 40–50% faster than conventional methods.

💰 Cost-Effective: Requires less material and labor.

🔧 Easy to Expand: Modular design allows quick expansion.

🌱 Eco-Friendly: Uses recyclable steel and produces minimal waste.

🏭 Versatile Applications: Ideal for factories, warehouses, workshops, and showrooms.

PEB systems align with Pakistan’s goal of promoting sustainable industrial development, especially under projects like CPEC industrial zones and export-oriented factories.

🏗️ How PEB Construction Works

The PEB process follows a systematic and engineered approach that ensures quality and efficiency.

🔹 Step 1: Concept & Design

Structural engineers create customized designs using advanced software like STAAD Pro and Tekla.

Load calculations are made based on wind, seismic, and live loads.

Architectural drawings are finalized according to site requirements.

🔹 Step 2: Fabrication

Steel members are fabricated in a factory with precision CNC machines.

Components are painted or galvanized for rust protection.

Quality inspection ensures compliance with AISC and MBMA standards.

🔹 Step 3: Transportation

Pre-fabricated components are shipped to the construction site in ready-to-assemble condition.

🔹 Step 4: On-Site Erection

Bolted connections make the structure easy to assemble.

Roofing, cladding, and insulation are installed.

Electrical and plumbing works are integrated seamlessly.

🔹 Step 5: Finishing & Handover

Final finishing touches like ventilators, skylights, and doors are added.

The building is tested for stability and safety before handover.

🧱 Key Features of ACCO’s PEB Solutions

ACCO Construction delivers custom-engineered solutions for industrial and commercial clients. Each project is designed for efficiency, durability, and aesthetics.

Our PEB Features Include:

🧩 Clear Span Design – No internal columns for maximum floor space.

🌡️ Thermal Insulation – Keeps interiors cool and energy-efficient.

💨 Natural Ventilation – Turbo ventilators and skylights.

🔩 Corrosion Protection – Galvanized or epoxy-coated steel members.

🔧 Low Maintenance – Long-term durability with minimal upkeep.

🏭 Applications of PEB Structures in Pakistan

| Sector | Application |

|---|---|

| Industrial | Factories, Power Plants, Assembly Units |

| Commercial | Warehouses, Showrooms, Shopping Plazas |

| Agricultural | Cold Storages, Poultry Farms, Greenhouses |

| Sports & Leisure | Indoor Arenas, Stadium Roofs |

| Institutional | Schools, Auditoriums, Workshops |

💰 Cost of PEB Construction in Lahore

PEB costs depend on size, material specifications, and design complexity.

On average, ACCO Construction offers PEB construction in Lahore at the following rates:

| Building Type | Estimated Cost (PKR per sq. ft.) |

|---|---|

| Basic Industrial Shed | 2,200 – 2,800 |

| Factory Building | 2,800 – 3,200 |

| Warehouse | 2,500 – 3,000 |

| Cold Storage / Insulated Building | 3,500 – 4,200 |

(Note: Prices vary based on design, accessories, and steel market trends.)

⚖️ PEB vs Conventional RCC Construction

| Feature | PEB Construction | Conventional RCC |

|---|---|---|

| Time | 3–5 months | 9–12 months |

| Cost | 20–30% less | High |

| Maintenance | Low | High |

| Flexibility | Easy to expand | Difficult |

| Strength | High tensile strength | Limited flexibility |

| Eco-Friendly | Yes | Moderate |

🌟 Pros and Cons of PEB Construction

✅ Pros

Faster completion and early ROI

Lightweight yet durable structure

Customizable design options

Easy relocation and expansion

Reduced labor and site waste

Excellent resistance to corrosion, fire, and earthquakes

⚠️ Cons

Limited architectural flexibility

Requires skilled erection team

Higher initial design precision needed

🔍 Why Choose ACCO Construction for PEB Projects in Lahore

ACCO Construction is among the most trusted PEB contractors in Pakistan, known for its dedication to innovation, engineering accuracy, and project reliability.

Why Clients Prefer ACCO:

🏗️ In-house design and fabrication unit

🧱 Premium materials and advanced technology

🕒 Timely project delivery

💼 Transparent pricing and documentation

🧰 After-sales maintenance and support

From industrial sheds to large manufacturing plants, ACCO ensures that every project reflects strength, precision, and performance.

📈 Trends in PEB Construction (2025 and Beyond)

🌱 Green Buildings: Integration of solar panels and rainwater harvesting.

🧠 Smart Warehousing: IoT-based automation systems.

🏗️ Hybrid Structures: RCC + Steel combinations for aesthetics and performance.

💡 BIM Technology: 3D modeling for accurate design visualization.

❓ Frequently Asked Questions (FAQs)

1. What does PEB stand for?

PEB stands for Pre-Engineered Building, a structure fabricated off-site and assembled on-site.

2. What is the life expectancy of a PEB?

Typically 30–40 years, depending on material quality and maintenance.

3. Can PEBs be customized?

Yes, ACCO Construction provides fully customizable PEB designs according to client needs.

4. Is PEB construction cheaper than RCC?

Yes, PEBs can be 20–30% more cost-effective due to reduced labor and faster timelines.

5. Are PEBs suitable for seismic zones like Lahore?

Absolutely. They are designed to withstand seismic and wind loads, making them ideal for Pakistan’s conditions.

🧭 Final Verdict

PEB construction has become the backbone of modern industrial development in Pakistan. Its speed, cost-effectiveness, and flexibility make it a game-changer for industries aiming for rapid expansion.

ACCO Construction combines technical excellence, modern engineering, and decades of experience to deliver reliable, affordable, and future-ready PEB solutions in Lahore and beyond.

If you’re planning a factory, warehouse, or industrial shed, choose ACCO Construction — where precision meets performance.

🔗 Internal Links

🌐 External Links

📞 Call to Action

Ready to build your factory or warehouse with advanced PEB technology?

👉 Contact ACCO Construction today for a free consultation!

📱 Phone/WhatsApp: +92 322 8000190

🌐 Website: www.acco.com.pk

📧 Email: info@acco.com.pk

Related Posts

Industrial PEB Construction Company in Sialkot – ACCO Engineering

Post a Comment cancel reply

You must be logged in to post a comment.