NFL Titans Changing the Game With $2.2B Nissan Stadium

[ad_1]

With its new Nissan Stadium, the National Football League’s Tennessee Titans are taking the fan experience to a new level. The $2.2-billion, 2.1-million-sq-ft venue will deliver an outdoor feel and a collection of indoor amenities in line with its hometown of Nashville. And it’s ready to cover much more than just football.

A nearly three-year construction period is set for completion in time to welcome as many as 60,000 fans for the first game of the 2027 football season.

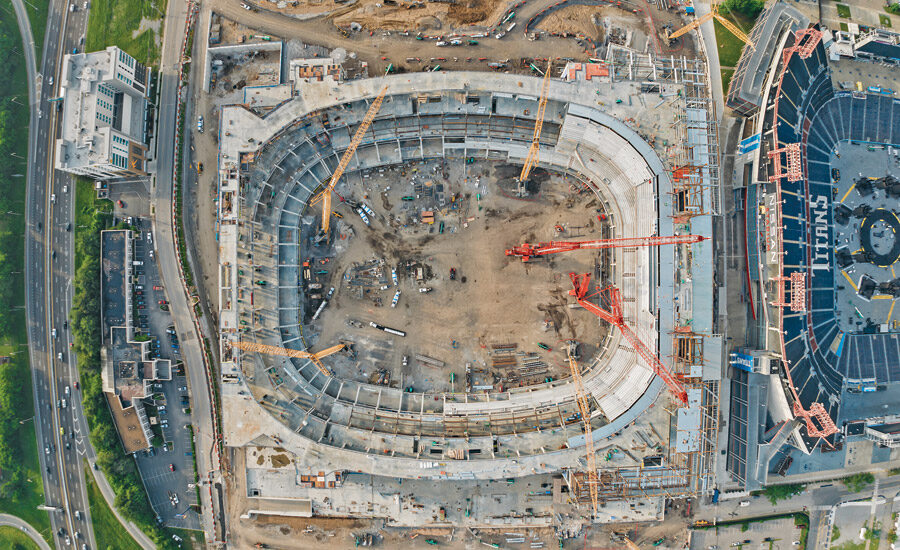

Built on the east side of the current Nissan Stadium alongside the Cumberland River, the new stadium is downsized in terms of seat numbers. It will have fewer than the 69,124 seats in the current stadium, but the team says it’s more focused on making sure that there “isn’t a bad seat in the house.”

The project is being built by the Tennessee Builders Alliance (TBA) Joint Venture of Turner Construction Co., AECOM Hunt, I.C.F. Builders and Polk & Associates Construction Inc.

Built on the east side of the current Nissan Stadium, the new venue has fewer seats than the current 69,124-seat stadium.

Photo by Donald Page/Tennessee Titans

John Gromos, senior vice president with Turner and principal for the JV, says the project is currently a little more than 40% in on the 34-and-a-half month schedule.

The February 2027 completion date gives the team a good bit of runway ahead of the first football game of the season so that the new stadium can host concerts or other events, says Kellen DeCoursey, project executive with the Titans.

“It’s been a great partnership (with TBA),” he says. “We’re excited where we are … the project has been a very thorough planning approach with TBA and the design team, so we haven’t seen many changes that cause issues or hiccups.”

current Nissan stadium is an aging facility with materials and infrastructure that are reaching the end of their usable life, and its prefabricated concrete frame isn’t suited to long-lasting renovation. It’s set for demolition following the completion of the new stadium.

The design team of MANICA as lead design architect and TVS as architect-of-record have put together a stadium that’s completely enclosed and climate-controlled with full interior halo board known as the “ring of fire.”

“When we set out to create the design of the stadium, we knew it had to fit into a new neighborhood,” says DeCoursey. “Working with MANICA, we kind of changed the game [of thinking that] football stadiums need to be elliptical or they need to be spaceship-shaped. It’s really a very civic building. It almost is going to operate and function like a large arena.”

Work began in spring 2024 with a major excavation of 400,000 cu yd of dirt moved from a sloped, 20-acre site, requiring the team to dig anywhere from 5 ft to 25 ft to get the site to level, Gromos says.

Drilled piers followed for the hybrid-frame structure featuring concrete through level 300 topped by steel. The last of 118 elevated cast-in-place slab pours concluded early in May, with concrete topping out May 4, he says. By mid-May, about 20% of the steel had been erected.

As of mid-May, the project team estimated that about 20% of the structure’s steel had been erected.

Photo by Donald Page/Tennessee Titans

Top-Notch Roof

Among the stadium’s most notable features is a non-retractable, 350,000-sq-ft cable-net ethylene tetrafluoroethylene (ETFE) roof system, which allows sunlight to filter through translucent, lightweight panels.

Only two other NFL stadiums boast a similar roof system that includes 38-ft spans, says Tyler Baumgardt, TBA vice president and AECOM Hunt vice president. Those are SoFi Stadium in California—also constructed by a Turner Construction-AECOM Hunt JV—and Allegiant stadium in Las Vegas.

“We were able to pull a fair amount of those individuals that were a part of that (SoFi project) and get all the lessons learned,” Baumgardt says, which was key in getting materials in time and the schedule coordinated. “We just have a really experienced team with a really solid plan.”

The roof is something the Titans wanted to pursue for several reasons, says DeCoursey, including attracting non-football events like wrestling matches and basketball games that would require a covered stadium and avoiding the higher construction and maintenance costs of a retractable roof.

“We just have a really experienced team with a really solid plan.”

—Tyler Baumgardt, Vice President, TBA & AECOM Hunt

“We had also integrated some outdoor experiences with our terraces and our operable door systems so that we didn’t feel like we needed to have an operable roof,” DeCoursey says, but “we really wanted to be able to play in daylight, to give people the experience that you’re kind of outside, but you do get the benefits of an enclosed environment.”

The lighter roof also translates to efficiencies that resonate all the way through the project, Baumgardt and Gromos note, including smaller cranes and a lighter structure all the way down to the foundation system.

“We’ve all done the retractable roof stuff,” Baumgardt says. “You end up spending a fortune not just on beefing up the building for the roof, but then the mechanization, and then you’re talking bigger cranes and longer schedule.”

The panels will be supported by cables as long as nearly 700 ft with a roof diameter of 660 ft, DeCoursey says. Those cables run through roughly 6-ft by 6-ft box beams via sleeves and are then tensioned from the back side to jack the roof into place, Baumgardt says.

“It’s basically a cable sleeve through a really big box beam on the ring beam on the roof,” he says.

Terraces offering views of the Nashville skyline are a key component, too, DeCoursey says.

“With MANICA and the design of the building, the overall orientation of it and where it is in downtown Nashville, we want to be able to offer people, even though we’re an enclosed environment, the ability to go outside,” he says. “Nashville is known for rooftops.”

The largest terrace, on the upper concourse, is nearly 60,0000 sq ft, he adds, saying that the most inexpensive tickets will be one of the best fan experiences in the NFL because of it.

“We focused on a great concourse experience,” he says. “I think that’s above and beyond the typical NFL concourses that really dress up the experience and wayfinding.… We’ve almost tripled the amount of different offerings.”

A 12,000-sq-ft multipurpose community space located right off the main entry is another key aspect, one that’s not football- or event-driven, and one which DeCoursey says can be used by groups Monday through Friday for things like training and seminars.

Compared with other stadiums, the Titans’ project features a lighter roof, which translates to efficiencies for its construction, including smaller cranes and a lighter structure all the way down to its foundation systems.

Photo by Donald Page/Tennessee Titans

Reaching the End Zone

Remaining slab-on-metal-deck concrete placements will continue as the project moves toward a May 2026 target date for substantial completion of structural elevated concrete decks. Structural steel and precast concrete stadia continue progression within the seating bowl and on the exterior west, north and south elevations.

Masonry is progressing on multiple stadium levels, as is interior light gauge framing on the mezzanine and main concourse levels, with exterior framing and sheathing on three facade elevations.

Utilities were roughed in last month, says Baumgardt, with work now moving to finish the rest of the building and prepare for the permanent power to come in the next eight to 12 months to “bring the building to life.”

As of May, 2,673 workers have compiled more than 1.5 million hours of work. Roughly 1,100 workers are on site every day, and Gromos says at peak, when interior work is at its busiest, the project will have as many as 2,000 on site, likely in the third quarter of 2026.

So far, the team hasn’t hit any unexpected snags, he adds, and work has been progressing on schedule.

“The schedule that we submitted during the pursuit of this project … the major milestones we have hit to the day,” he says, adding that there have been the normal daily coordination issues and conflicts, but “there haven’t been major issues that we sometimes see in other projects.”

The project has also been able to weather workforce issues due largely to the high-profile nature of a major sports project, says Baumgardt.

“When you go for these mega sports projects, you just get so much national attention from the [subcontractor] market that then you pull the national labor force in, and so it doesn’t overstretch the local market,” he says, adding that the local market is still heavily involved in the project.

As steel erection continues, the project team is trying to keep up to speed on federal tariff policy that might impact costs of steel imports, though most of the steel for the project was ordered much earlier, Baumgardt says.

Additionally, many of the materials are coming from domestic sources, he says, and the project may feel the brunt of the tariffs only in small, select electronics and other parts.

As of May, 2,673 workers have compiled more than 1.5 million hours of work.

Photo by Donald Page/Tennessee Titans

The challenge is not unique to this project but rather is an ongoing conversation project teams are having around the country, and one constantly changing with daily or weekly updates, Gromos says. He also notes that long-lead items were mostly electrical components, and those were aggressively targeted for early release packages that have largely gone according to plan.

“Nobody has a crystal ball that can forecast what it looks like,” he says. “So we’re having a lot of conversations about if and when it hits, how do we account for it? How is the right and fair way to address it?”

The completed project, which is targeting a LEED Gold certification, will capture rainwater from the roof in 400,000 gallons of cistern collection tanks that will be reused for HVAC, toilet flushing and irrigation, DeCoursey says.

“One of the things that we’re really excited about is what the operations of the building will look like,” he says.

That includes an 8,000-sq-ft resource recovery room for waste handling, which in partnership with Waste Management will sort and recycle material for the Titans’ goal of operating a zero-waste facility.

Wrap all that together, and it’s a new era not only for the Titans, but for Nashville and the surrounding area, too, says DeCoursey.

“I think the ability to host the amount of events and what that means for Nashville and Tennessee, and we’re already a city on the rise. I think this is going to bring us to the next level, and it’s very exciting to see,” he says.

[ad_2]

Source link

Post a Comment

You must be logged in to post a comment.