Prefabricated Industrial Shed Manufacturers

Introduction to ACCO Engineering

As civil construction continues to evolve, the demands on construction sites are increasing rapidly. To meet these growing needs, prefabricated industrial sheds have become essential due to their quick installation, easy disassembly, and cost-effectiveness.

ACCO Engineering, a top manufacturer of prefabricated structures, offers premium solutions for industrial sheds at competitive construction costs. The widespread adoption of pre-engineered buildings (PEB) has made prefabricated industrial sheds a popular choice across various industries.

ACCO Engineering has earned a reputation as one of the fastest-growing industrial shed manufacturers and suppliers in Pakistan, providing efficient and durable solutions tailored to the needs of the construction industry.

Best-in-class industrial shed features

At ACCO Engineering, we prioritize custom-designed architecture and client-specific construction in all our prefabricated structures. As one of the leading industrial shed manufacturers in Pakistan, we focus on delivering solutions that perfectly match the unique requirements of our clients, supporting their growth and success. By utilizing high-quality raw materials and a meticulous manufacturing process, our industrial sheds come with a lifetime guarantee of durability and reliable service.

- Rugged Design: Built to offer exceptional longevity and withstand harsh conditions.

- Resistance to Rust, Moisture, and UV Rays: Ensuring a long-lasting, low-maintenance solution for diverse environments.

- Fast Installation: Our rapid construction method is far quicker than traditional shed building.

- Fire-Resistant Design: Optimized for safety with superior fire-resistant properties.

- Cost-Effective: Providing an affordable construction alternative without compromising quality.

Prefabricated Industrial Shed: Durable, Efficient Solutions for Modern Industries

Introduction

In today’s industrial world, speed, efficiency, and scalability are critical to business success. A prefabricated industrial shed is a modern building solution engineered off‑site and assembled on‑site to meet diverse industrial needs such as warehousing, manufacturing, storage, and logistics. Unlike traditional construction methods that are time‑consuming and costly, prefabricated sheds save time, reduce waste, and offer unmatched design flexibility. honglusteel.com

As industries grow and production demands rise, choosing the right partner for constructing these structures becomes vital. ACCO Engineering & Construction delivers premium prefabricated industrial sheds that balance structural strength, speed of delivery, and cost‑effectiveness. With services spanning from initial design consultation to final erection and maintenance, ACCO ensures industrial sheds are tailored exactly to operational requirements. Throughout this guide, you’ll learn the key features, advantages, applications, cost considerations, and why ACCO should be your trusted provider of prefabricated industrial shed solutions.

What Is a Prefabricated Industrial Shed?

A prefabricated industrial shed is a pre‑designed steel building constructed using factory‑manufactured components such as frames, purlins, roof and wall panels, and structural steel elements. These parts are produced under controlled conditions to ensure quality and consistency, then transported to the construction site for rapid assembly. honglusteel.com

Key Characteristics

Factory‑produced components with high precision

Modular and scalable design for future expansion

High structural integrity with steel frameworks

Quick on‑site assembly compared to traditional builds

Low maintenance and long lifespan due to durable materials Shed Manufacturer

Whether you need a warehouse, workshop, or storage facility, prefabricated industrial sheds are adaptable to virtually all industrial environments.

Core Components of a Prefabricated Industrial Shed

Understanding what makes up these structures helps clarify their performance advantages:

1. Structural Frame

The primary strength comes from a steel frame designed to withstand heavy loads and industrial conditions. ACCO uses high‑tensile steel frames engineered to match project specifications, ensuring resistance against wind, seismic activity, and heavy equipment operations. jaywantgroup.com

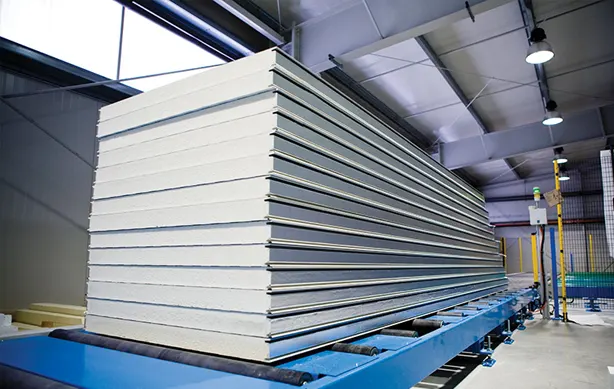

2. Roof and Wall Cladding

Roof and wall panels are typically made from insulated steel sheets or sandwich panels, providing protection from weather, improved thermal performance, and energy efficiency. Shed Manufacturer

3. Secondary Members

This includes purlins, girts, and braces that support the primary frame and provide overall stability and strength.

4. Doors & Access Facilities

Sheds can be customized with roller shutters, sliding doors, ventilation openings, and loading dock access tailored to operational needs. jaitrainfratech.com

5. Insulation & Ventilation

Insulated panels and natural ventilation systems help regulate internal temperatures, improve worker comfort, and reduce energy costs. jaywantgroup.com

Major Advantages of Prefabricated Industrial Sheds

Faster Construction & Turnkey Delivery

Since parts are manufactured off‑site, assembly on site is quick — often completing projects in a fraction of the time required for traditional construction. This approach reduces labor costs and accelerates operational readiness. honglusteel.com

Cost Efficiency

Prefabrication reduces material waste and on‑site labor, making sheds more cost‑effective. This allows businesses to reinvest capital into core industrial activities or equipment upgrades. Shed Manufacturer

High Durability & Low Maintenance

Steel structural systems are resistant to weathering, pests, fire, and corrosion, translating to decades of dependable use with minimal upkeep. fiberglass.pk

Customization & Scalability

Prefabricated industrial sheds can be customized in dimensions, layout, insulation levels, mezzanine floors, or integrated office spaces — supporting future expansion as your business grows. Shed Manufacturer

Eco‑Friendly Construction

Factory production reduces waste, and steel is highly recyclable, aligning with green building goals and reducing environmental impact. fiberglass.pk

Design Considerations for Industrial Use

When planning a prefabricated industrial shed, consider the following:

Clear Span Width

Large unobstructed floor spaces optimize storage or production flow and reduce interior columns that interfere with operations.

Roof Slope & Drainage

Proper roof design ensures efficient rainwater drainage and prevents water accumulation, prolonging the life of roofing materials.

Insulation & Climate Control

In warmer regions, insulation is critical for comfort and energy efficiency, helping maintain internal temperatures for both people and stored materials.

Loading & Access Layout

Optimized door placement and access points improve movement efficiency for forklifts, trucks, and personnel.

ACCO’s engineering team works with clients to tailor these elements to the specific operational requirements of the business.

Applications of Prefabricated Industrial Sheds

Prefabricated steel sheds are versatile and serve various industrial applications, including:

Warehousing & Logistics: Efficient layouts for material storage and distribution. silversteelmills.com

Manufacturing Plants: Flexible workshop areas and production zones. silversteelmills.com

Cold Storage Structures: Integrated insulation systems for temperature control. goldensteelmill.com

Agricultural Processing: Storage and processing space for produce or equipment. silversteelmills.com

Heavy Machinery Workshops: High‑strength sheds for industrial machinery and repair bays. silversteelmills.com

ACCO’s sheds are engineered for all of these uses, backed by professional design and support services.

Cost Factors & Budgeting

The price of a prefabricated industrial shed varies based on multiple factors:

Size and dimensions

Type of wall and roof materials

Insulation requirements

Customization options like mezzanine floors or office spaces

Foundation and site preparation silversteelmills.com

In Pakistan and nearby regions, basic prefab sheds typically range from PKR 900 to 2,500+ per sq. ft, depending on specifications and materials. silversteelmills.com ACCO provides transparent cost breakdowns and quotations tailored to site conditions and project goals.

Safety & Quality Standards

Prefabricated industrial sheds must satisfy rigorous safety and building codes. ACCO ensures compliance with structural standards, fire safety requirements, and environmental guidelines to deliver safe, long‑lasting buildings. Regular inspections, certified materials, and quality assurance processes support superior build integrity.

Why Choose ACCO for Your Prefabricated Industrial Shed?

ACCO Engineering & Construction stands out for industrial shed projects due to:

Full‑Cycle Services — From site survey and design to fabrication, assembly, and after‑sales support.

Custom Solutions — Tailoring every project to industry‑specific needs.

Quality Assurance — Use of high‑grade steel and precision fabrication.

Timely Delivery — Efficient project timelines that minimize business disruption.

Professional Support — Experienced engineers and project managers throughout.

With a commitment to excellence, ACCO delivers prefabricated industrial shed structures that enable businesses to operate efficiently and grow sustainably.

Frequently Asked Questions (FAQs)

1. What is a prefabricated industrial shed?

It’s a steel‑based, factory‑manufactured structure assembled on‑site for industrial use, offering strength, scalability, and faster construction. honglusteel.com

2. How long does it take to install a prefab industrial shed?

Typically, prefabricated sheds can be erected in a fraction of the time needed for traditional construction, often weeks instead of months. honglusteel.com

3. Are prefabricated sheds suitable for warehousing?

Yes — they provide large clear span spaces ideal for logistics, inventory storage, and distribution centers. silversteelmills.com

4. Can a steel industrial shed be insulated?

Absolutely. Insulated panels can reduce heat transfer and improve energy efficiency. jaywantgroup.com

5. Do prefabricated sheds require high maintenance?

No — steel sheds are low‑maintenance and durable with corrosion‑resistant coatings. Shed Manufacturer

Conclusion

Prefabricated industrial sheds have revolutionized industrial infrastructure by offering faster construction, cost‑efficiency, design flexibility, and long‑term durability. These structures suit a wide range of industrial applications, from warehousing and manufacturing to cold storage and agricultural processing. With professional providers like ACCO Engineering & Construction, businesses gain fully custom solutions backed by expert design, high‑quality materials, and efficient project delivery.

Whether you’re planning to expand operations, build a new facility, or upgrade storage capacity, a prefabricated industrial shed is an intelligent, future‑ready investment that supports growth and operational success.

Construction Building We Build

Specifications of Industrial Shed Components

ACCO Engineering offers prefabricated industrial sheds with high-quality materials tailored to client needs:

- Walls: PUF/EPS insulated sandwich panels (50mm/60mm), with PPGI sheets on both sides.

- Roof: PUF/EPS insulated sandwich panels (30mm/40mm) or PPGI roofing sheets.

- Doors: Insulated doors with accessories, sourced from our manufacturing setup.

- Windows: Aluminum anodized sliding windows.

- Structure & Accessories: All supporting accessories and structure provided before delivery.

- Fittings: Electrical, sanitary fittings, beds, etc., as per client specifications.

Industrial shed Applications

The wide range of PEB industrial sheds that ACCO Engineering makes are best suited for construction requirements in almost all industries from aeronautical to food and beverages or any other. Another beneficial feature of the sheds is that more insulation support can also be added to them for meeting specific construction regulations and can lead to great alternate options for greater energy savings and low consumption.

The best of the industrial sheds manufactured by ACCO Engineering find applications as following:

- Transport industry

- Chemical industry

- Manufacturing centers

- Warehouses

- Commercial outlets

Benefits from ACCO Engineering

ACCO Engineering stands out in the industry by utilizing high-grade materials and an intricate production process, giving us a competitive edge as a top industrial shed manufacturer and supplier in Pakistan. Our focus on delivering products tailored to specific customer requirements has been key to our success.

Benefits of ACCO Engineering Prefabricated Industrial Sheds:

- Versatile Usage: Ideal for storage, workshops, and warehouses across various industries.

- High-Quality Materials: Built using premium materials for durability and strength.

- Large Covered Areas: Perfect for constructing expansive spaces efficiently.

- Cost-Effective: Designed to meet your specific needs while being affordable.

ACCO Engineering is committed to providing high-quality, customizable, and cost-effective industrial shed solutions.

Frequently Asked Questions (FAQ)

What is an industrial shed?

Industrial sheds are structural buildings. These are built by businesses that need to store raw materials. They are also used for producing goods. One can use them for storage facilities, godowns, factories, and other such purposes.

Who are the best Industrial Shed Manufacturers in Pakistan?

Pakistan hosts several top-tier industrial shed manufacturers known for their quality and innovation. Leading the pack is ACCO Engineering, a company with 24+ years of experience. This company offers a range of solutions tailored to meet the diverse needs of various industries, ensuring durability, cost-effectiveness, and quick assembly.

How much does it cost to build an industrial shed in Pakistan?

The cost of building an industrial shed in India is highly variable. It depends upon the area, the locality, the need for insulation, and other such factors. The industry for which the shed is needed is another important factor. Prefer partners that offer good quality, efficient, and environment-friendly products.

Are prefab sheds worth it?

Yes, prefab sheds are worth it due to their numerous advantages. They are cost-effective, easy to install, and customizable. Prefabricated sheds offer great durability and require minimal maintenance, making them a popular choice for both residential and commercial applications. Their quick construction time and adaptability to various needs make them a practical investment.

How many types of Industrial Sheds are there?

There are many kinds of industrial sheds depending on materials and requirements. The common ones are prefabricated sheds, PEB sheds, factory sheds, and warehouse sheds. Every shed has a unique design and specific features that meet the demands of the client.

What is the difference between an industrial shed and a warehouse?

Many people mistakenly believe that these two types of spaces are interchangeable, but that couldn’t be further from the truth. Commercial warehouse space is designed for storage and distribution, while industrial space is built to accommodate complex manufacturing processes.

Who are the top industrial shed manufacturers in Pakistan?

Some of the top industrial shed manufacturers in India include ACCO Pakistan. This company is renowned for its high-quality materials, innovative designs, and efficient construction processes, catering to a wide range of industrial requirements.

What are the benefits of prefabricated industrial sheds?

There are multiple reasons to prefer commercial sheds made with prefabrication. They are readily available, low-maintenance structures that are highly resistant to weather extremes. Due to its sturdiness and all other features, prefabricated steel sheds are becoming popular in Pakistan.

What is a prebuilt shed?

A prefab (prefabricated) shed is made beforehand and delivered right to your doorstep. They are custom-made structures made by experts that you can buy from a sales lot or online. Prefab structures come in a wide variety of materials, colours, sizes and styles and can be customized to your specific needs.

What does the ACCO Engineering company do?

ACCO Engineering makes end-to-end solutions with prefabrication and pre-engineering technology. It can make different structures, from infrastructure to sports and institutional buildings. Their prefabrication services are highly preferred for industrial sheds.