How PEB Improves Safety, Strength & Earthquake Resistance

By ACCO Engineering

Introduction to ACCO Engineering

ACCO Engineering is a leading name in Pakistan for Pre-Engineered Buildings (PEB), industrial steel structures, and turnkey construction solutions.

Based in Lahore, ACCO Engineering has extensive experience in designing, fabricating, and installing industrial warehouses, factory sheds, and commercial steel structures across Pakistan.

Specializations include:

-

PEB design and engineering

-

Industrial warehouse construction

-

Turnkey industrial projects

-

Earthquake-resistant steel structures

-

Steel fabrication and installation

ACCO Engineering ensures all projects meet international safety standards while being cost-effective and time-efficient.

🚀 Topic Introduction

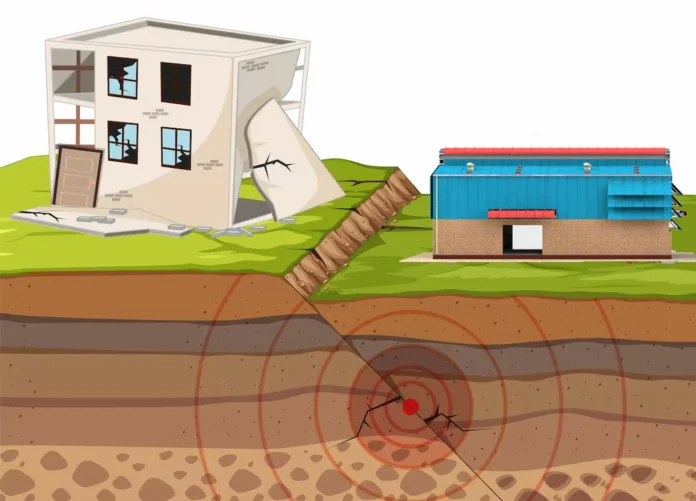

In Pakistan, earthquakes are a real risk, especially in industrial and densely populated areas. Traditional RCC structures may not always provide the flexibility and strength required for modern industrial needs.

Pre-Engineered Buildings (PEB) are emerging as the preferred solution due to their enhanced safety, superior strength, and earthquake resistance.

Using Earthquake Resistant PEB Structures, industries can:

-

Protect assets and workforce

-

Minimize downtime after seismic events

-

Ensure long-term operational safety

-

Save on construction and maintenance costs

🏗️ Complete Details: How PEB Improves Safety, Strength & Earthquake Resistance

PEB buildings are engineered with precision to handle dynamic loads, seismic events, and harsh industrial conditions. Below is a detailed breakdown.

🔹 1. Structural Strength of PEB Buildings

PEB structures are designed to handle:

-

Heavy machinery loads

-

Material storage and movement

-

Wind and snow loads (where applicable)

-

Dynamic seismic forces

Key Features:

-

High-strength steel frames

-

Bolted connections for flexibility

-

Wide column spacing for open interior layouts

-

Lightweight steel reduces seismic inertia

Comparison Table: PEB vs RCC for Strength

| Feature | PEB Structure | RCC Structure |

|---|---|---|

| Weight | Lighter | Heavier |

| Seismic Response | Flexible, absorbs shocks | Rigid, more prone to cracks |

| Construction Time | 45–90 days | 6–12 months |

| Expansion | Easy | Costly & slow |

| Maintenance | Low | High |

🔹 2. Earthquake Resistance

PEB buildings are ideal for seismic zones because:

-

Steel flexibility allows movement without failure

-

Bolted connections absorb earthquake energy

-

Lighter roof reduces load on walls and foundations

-

Structural frames can be designed to meet Pakistan Seismic Code

Why it matters in Pakistan:

Pakistan lies in moderate to high seismic zones (Northern regions, Baluchistan, and parts of Punjab). Using Earthquake Resistant PEB Structures is a proactive safety measure.

🔹 3. Safety Features

PEB buildings ensure:

-

Fire-resistant coatings on steel

-

Proper ventilation and emergency exits

-

High-quality anchor bolts for stability

-

Non-combustible wall and roof sheeting

-

Minimal risk of structural collapse

Safety Benefits for Industries:

-

Protect workers during earthquakes

-

Prevent asset damage

-

Reduce insurance premiums

-

Maintain continuous operations

🔹 4. Fast Construction and Reduced Downtime

PEB buildings are faster to construct than traditional RCC structures:

-

Fabrication off-site reduces delays

-

Modular components simplify erection

-

40–60% faster construction

-

Minimal disruption to ongoing operations

Faster construction reduces exposure to risk and allows industries to be operational sooner.

🔹 5. Cost-Effectiveness & Lifecycle Benefits

-

30–40% lower initial cost compared to RCC

-

Reduced maintenance costs

-

Ability to expand or modify easily

-

Long-term durability (50+ years)

-

Less damage in earthquakes reduces repair expenses

🔹 6. Design Flexibility

PEB buildings allow:

-

Open interior spans for machinery and workflow

-

Flexible layouts for production optimization

-

Roof and wall customization for insulation or ventilation

-

Seismic design optimization

PEB = Safety + Operational Efficiency

⚖️ Pros & Cons of PEB for Earthquake Resistance

✅ Pros

-

Earthquake-resistant design

-

Lightweight yet strong

-

Fast construction & modular

-

Easy expansion and retrofitting

-

Low maintenance and durable

-

Fire and corrosion-resistant

❌ Cons

-

Requires professional engineering for seismic zones

-

Limited architectural detailing compared to RCC

-

Transport logistics for large steel members must be planned

❓ Frequently Asked Questions (FAQs)

1. Are PEB buildings safe during strong earthquakes?

Yes. Steel frames absorb seismic energy, minimizing structural damage.

2. How long does it take to construct a PEB industrial shed?

Typically 45–90 days depending on size and complexity.

3. Can PEB structures be customized for industrial needs?

Absolutely. PEB allows flexible column spacing, roof height, and internal layouts.

4. Are PEB buildings cheaper than RCC?

Yes, PEB structures save up to 40% in construction costs.

5. Do PEB buildings require special maintenance after an earthquake?

Minor inspections are recommended, but structural repairs are rarely needed.

🧩 Internal Links (for your website)

🌍 External Links (High Authority Sources)

-

PEC Pakistan – Engineering Standards

🏁 Conclusion

PEB buildings are the ideal solution for modern industrial construction in Pakistan, combining:

-

Earthquake-resistant design

-

Superior structural strength

-

Worker and asset safety

-

Fast construction and cost-efficiency

Investing in Earthquake Resistant PEB Structures ensures long-term safety, operational continuity, and compliance with seismic regulations.

Contact ACCO Engineering today for a free consultation!

🌐 www.accoengineering.com

📧 info@accoengineering.com

📞 WhatsApp: 0322-8000190

Related Posts

Post a Comment cancel reply

You must be logged in to post a comment.