States Eye Technology to Improve Highway Work Zone Safety as AGC Releases Report

Highway construction workers remain vulnerable to work zone crashes as a result of distracted or speeding drivers, according to a new Associated General Contractors (AGC) national survey. State transportation agencies are exploring ways to increase safety awareness through pilot projects such as using telematics in connected construction equipment.

Sixty percent of contractor respondents reported at least one work zone car crash during the past year, with nearly one-third experiencing five or more such incidents. At least one construction worker sustained injuries injured in 30% of the reported work zone crashes, while 13% resulted in at least one worker fatality. Respondents cited districted and impaired driving, speeding and driver impatience among the leading causes of work zone crashes.

“These workers are counting on the traveling public to slow down and pay attention,” Jeffrey D. Shoaf, AGC’s chief executive officer, told a press briefing, “but too often, the public is letting them down.”

Motorists are at even greater risk of injury or death from work zone crashes. More than 71% of contractors reported experiencing an incident in which drivers or passengers were injured, while 24% resulted in at least one motorist fatality.

AGC and other industry advocates have long pressed Congress and state lawmakers to enact measures they say would improve highway work zone safety, including increased on-site police presence and stricter fines for speeding and cell phone use in these areas. Yet the danger persists, as 47% of respondents feel that crash risks at their work zones have increased over the past year —a figure virtually unchanged from AGC’s 2024 study.

Lingering concerns about privacy and use of speed camera data have hampered efforts to gain approval of the technology as a means of enforcing work zone safety. For example, a bill proposing the use of safety speed cameras in work zones failed to advance in the most recent session of the Texas Legislature, even though the measure would have required driver citations to be issued on site by a police officer, rather than a third-party system operator. Another bill requiring work zone safety to be incorporated into the state’s driver education program was approved and has since been signed into law by Gov. Greg Abbott (R).

AGC’s work zone safety study was based on a nationwide survey of highway construction firms conducted in April and May 2025 by the association and construction software developer HCSS. More than 600 contractors participated in the survey.

DOTs Pursue Technology-Aided Safety Ideas

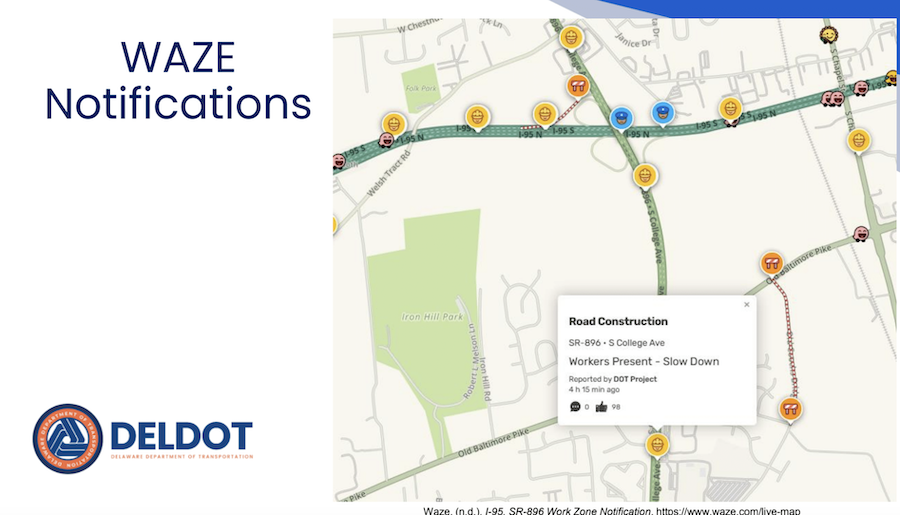

State transportation agencies are exploring other ways in which technology can augment conventional approaches to alerting motorists to the presence of construction work zones. As part of its Accelerating Digital Inspection Practices with Connected Machinery (ADCMS) project, the Delaware Dept. of Transportation (DelDOT) has been collaborating with local highway contractors and technology providers on ways to share telematics data collected from work zone construction equipment with systems that support vehicle navigational aids such as in-car maps.

DelDOT construction resource engineer Cassidy Blowers explains that the system is designed to automate notifications based on a quick setup at the start of a project. “From that point forward, normal work processes trigger the automated notifications,” she says. “These notifications currently integrate with Waze and FHWA’s Work Zone Data Exchange.”

Blowers adds that DOTs in Louisiana, Iowa, and Nebraska are also experimenting with the ADCMS platform, which had been implemented on 26 projects as of October 2024. “We’re working to encourage additional states to take advantage of this as well,” she says.

The multistate pilot project to evaluate the material delivery ticketing app HaulHub has evolved into a comprehensive effort to track all heavy equipment on state highway jobsites in real time using onboard telematics and advanced data processing, she said in a presentation at ENR’s FutureTech conference, held May 6-7 in San Francisco.

“Telematics is there, and fortunately for us as a DOT, there is an ISO specification for us to harvest he information … and apply some very basic construction logic to make a site safer,” she said.

With the contractors’ permission, DelDOT pulls in equipment location and activity data and can automatically generate digital notifications about active work zones for drivers and the rest of the public. “So what we ask for our contracting partners is to share that information with us, and then we apply our logic in a simple manner, get the equipment’s active, then we know we have staff on site, then we should be giving a notification to the public.

The pilot resulted in 600 connected pieces of construction equipment, she said. She added that “we want to expand that information to not just a paver, not just a roller, not just a material ticket, but any piece of equipment…We can harness that information to get a safety notification out there.”

But safety is just the first step, and Blowers’ agency is excited to use the statewide data to rethink how to plan and stage projects, including with low carbon footprints in mind. “Fuel use factors into the carbon calculation, the impact of the project,” she said. “We’re having discussions with the OEMs, trying to drive additional sensor adoption…because we want to be able to harness that information and use it to make our lives easier—not just for our own ends, but also for the contractors. We want everybody to be on the same page.”

AI could be a way to address the chronic shortage of skilled workers in the industry, Blowers added. “We are desperate for more people. We just can’t fill positions. We need to make our inspectors more efficient for what we have.”

For example, AI could help teams handle the “boatload of data” coming in from the connected equipment. “We need to summarize that in an easy way. We try and make life easier for the inspector using all our different data sources—material ticketing information, ticket equipment data, traffic data, weather data—and try and standardize the report,” she said. “We want to make our limited inspection staff more efficient and more consistent in the reporting.” The hoped-for result would be reports that enable inspectors to “instead of measuring what was done and calculating what was done, they can just verify what the equipment already says was done.”

Connecting construction equipment to autonomous vehicles is another possibility, as is using data to enhance asset management. “A year ago, we didn’t have the ability to say, ‘well, this drainage inlet that was supposed to be installed at this location is actually installed [over] there’…There wasn’t a way to put it in a latitude-longitude for them to use. We put it in a station offset, and then a surveyor came in later and did it. And that’s double work,” she said as an example. “And we can’t be asking for double work. We need something that benefits us and [contractors] at the same time.”

Post a Comment

You must be logged in to post a comment.