New Technical Document Available on Transitioning Polypropylene Pipe

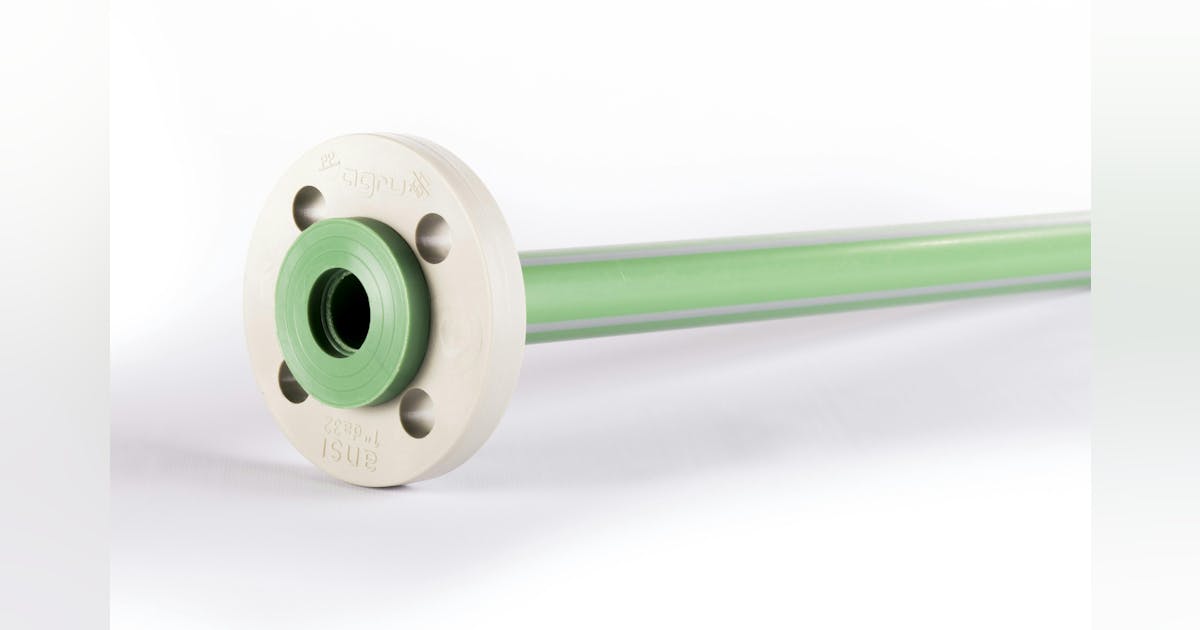

IRVING, TX — The Plastics Pipe Institute’s (PPI) Building & Construction Division’s new technical document provides design and installation recommendations for transitioning from polypropylene pipe to other piping materials using flange adapters and connections. PPI TN-71, “Flanges and Flange Adapters for Polypropylene (PP-R & PP-RCT) Piping Systems”, is now available at the division’s website.

Polypropylene (PP-R and PP-RCT) pressure pipe and fittings are usually joined to each other by butt fusion, socket fusion, sidewall outlet fusion, or electrofusion methods. ASTM recently published the new ASTM F3722-24 “Standard Practice for Heat Fusion Joining of Polypropylene (PP) Pipe & Fittings” to give guidance on joining those types of fusion connections.

Flanged Assemblies

Flanged assemblies are commonly used for connections to fittings and valves from PP pipes to pipes of other materials (e.g., CPVC, HDPE, steel), or as end connections on fabricated pipe spools and assemblies.

According to Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division, “Flanged joints prevent leakage by compressing a deformable gasket material into irregularities in a less deformable material to seal possible leak paths. The mating faces of flanged joints are the surface areas that need to be sealed. The deformation characteristics of the material, which includes gasket hardness, compressive strength, and compression set, are the primary determinant of the amount of compression, expressed as force per unit area, or pressure, required to properly seal a flanged joint.”

Post a Comment

You must be logged in to post a comment.