Building the Hoover Dam Drove Engineers to New Heights

[ad_1]

The Colorado River was a fault line of near-tectonic political forces by the 1920s, as the seven states within its basin continued to grow in population. A 1922 compact allocated water rights from the river, but farmers in California’s Imperial Valley suffered from unpredictable flows and called for a dam that would provide flood control and a consistent supply of irrigation water. Officials in Los Angeles sought additional water for their expanding city, while politicians and business interests eyed the potential for power generation. This all set the stage for Congress approving a plan in 1928 to dam the river.

Set to be the world’s tallest dam at 729 ft, exceeding the then-record 417-ft Owyhee Dam in Oregon, the Hoover Dam was an unprecedented project, with the Bureau of Reclamation conducting research on physics, mechanics, elasticity, hydraulics, chemistry, seismology and structural geology.

It developed “new mathematical equations, new methods of stress analyses, new methods of model testing, new specifications for cement, and new determinations of the thermal properties of concrete,” according to a 1932 ENR article by Elwood Mead, the Bureau’s commissioner.

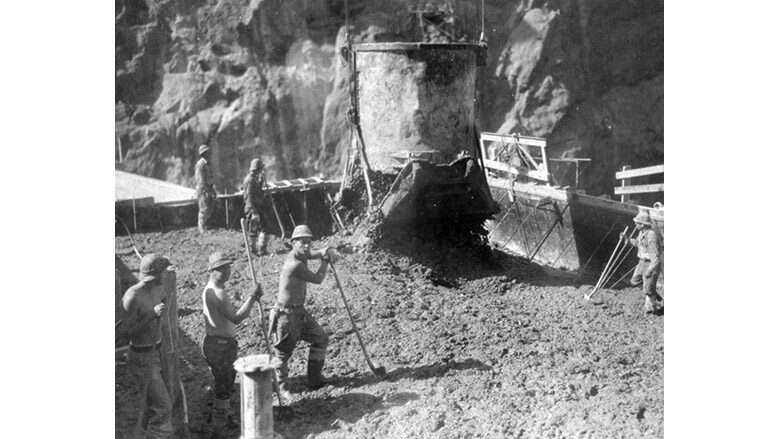

Illustration from ENR Archives

Once it was decided an arch-gravity dam would be constructed, accuracy of the trial-load method of analysis had to be established. Thus, “it was necessary to determine accurately the effects of tangential shear, twist, Poisson’s ratio, flow, internal temperature variations, radial cantilever sides, foundation and abutment deformations, earthquake shocks, spreading of canyon walls due to reservoir water pressure, uplift pressure within the pores of the concrete.”

The Bureau received three bids, and awarded the contract to Six Companies Inc., a joint venture, in 1931. The chosen site, Black Canyon, was 30 miles from Las Vegas, population 9,000. It was the height of the Great Depression, and over 10,000 unemployed people converged on Las Vegas hoping to get hired even before the contract was awarded. A surveyors camp near the dam site was soon encircled by a squatters camp known as McKeeversville. Another encampment near the river was known as Ragtown. Fifty-nine miles of railroad were laid, involving heavy grading, five tunnels, and a timber trestle across the river. A 225-mile transmission line was erected to bring power to the site. A planned town of modest houses for 5,000 workers was built, called Boulder City. Alcohol and gambling were banned, and workers had to enter through a gatehouse.

Cover from ENR Archives

A record-setting, 150-ton capacity cableway was installed and used to ferry 46,000 tons of penstock pipe sections to four platforms in the canyon, as well as gates, valves, power plant gear, machinery, and even trucks. Cement came from four plants in California, delivered by rail and mixed on site. An onsite aggregate plant produced 500 tons per hour.

The first major task was excavation of four massive diversion tunnels, each 4,000 ft long and 56 ft in dia. Adits were driven into the canyon walls at tunnel midpoints, providing, with portals, four points of attack in each tunnel. Workers used pneumatic diamond-tipped drills to core holes, which were packed with dynamite and blasted. Mobile drilling rigs, consisting of three-level platforms mounted on flatbed trucks, let a dozen or more drillers drill simultaneously into the tunnel faces as 100-ton electric shovels removed rubble.

When rock conditions were ideal and supports weren’t needed, tunnels were lined with 3 ft of concrete for durability and smooth water flow. Continuous convoys of trucks delivered 2 cu yd buckets of concrete from the batch plant. Rolling gantries were used to place the concrete for the inverts and sides. A rolling rig called the sidewall jumbo—a huge curved metal form with dozens of metal chutes—delivered concrete for tunnel walls. Men followed behind the form to work the concrete against the rock. Concrete for the uppermost tunnel arch sections was pumped through hoses to pneumatic concrete guns. Finally, grout was injected into the surrounding rock.

The dewatering process began after the river’s diversion into the tunnels in November 1932. Rubble was piled in the river and water pumped out, exposing the riverbed. Cofferdams were built upstream and downstream of the dam site. The larger upstream one was impressive in itself, at 98 ft high, containing 568,000 cu yd of earthfill and 157,000 cu ft of rock, with its upstream slope faced with a concrete slab. Excavated spoil and gravel fill were transported to and from both cofferdams by rail. The cofferdams were completed in the spring of 1933, well in advance of the flood season.

Perhaps the most spectacular workers were the “high scalers”—one hundred men, suspended by ropes, prying loose unsound rock from the canyon walls with pneumatic jackhammers, followed by drilling and blasting. This was done for the sites of the four water intake towers, the downstream powerhouse, as well as the main dam abutments. Abutment excavation took a year and completed in mid-1933. Riverbed excavation involved removal of silt, sand and rock over 100 ft down before hitting bedrock.

The dam’s designer was John L. Savage, chief design engineer for the Bureau of Reclamation. He oversaw design for 60 large dams and consulted on hundreds of others in 19 countries.

The dam’s wedge shape consists of hundreds of interlocking concrete columns, varying from 55 ft x 60 ft at the upstream face to 25 ft x 30 ft at the downstream face. Corduroy-like ridged edges on the blocks help them nest together and resist movement under pressure. As casting progressed, the blocks rose 30 ft per month on average. Circumferential and radial joints helped blocks resist and distribute pressure from the upstream side. Concrete was supplied in 20-ton, 8-cu-yd buckets by cableway, and cast in 5-ft lifts for each block. It took up to 100 buckets to fill each lift.

The foremost technical challenge was dissipating the tremendous heat emitted by the concrete as it cured, which if not addressed would lead to cracking. A system of 300 miles of 1-in.-dia pipes carrying chilled water were installed between each lift, lowering the temperature of the concrete to 54° F before placing the next lift, quite a challenge during brutally hot Nevada summers. Grouting was done using perforated pipes placed in every vertical and horizontal joint, and a three-row grout curtain was installed in the entire abutment, from rim to canyon rim. Concrete placement began in June 1933 and went steadily, averaging 6,000 cu yd per day, with grouting completed in June 1935.

The dam is laced with networks of internal galleries for inspection, water drainage and grouting. With a 660-ft maximum width at the base, tapering to 45 ft at the 1,180-ft-long crest, the 3.25-million cu yd monolith plugged the river and created the largest artificial reservoir in the U.S.

The dam’s four intakes are 380-ft-tall reinforced concrete towers housing 32-ft-dia shafts that feed into two of the diversion tunnels. They adjust the flow to supply downstream generators at a steady, precalculated water pressure. Design calculations called for intake pipes to be 30 ft in dia, so 30-ft-dia steel penstocks were installed inside the diversion tunnels. Penstock sections were fabricated on site by Babcock & Wilcox Co., and hauled into the diversion tunnels through adits in the canyon walls. Two types of valves maintain pressure and water flow through the penstocks and generators. Butterfly valves 14 ft in dia control water going to the turbines. Two sets of six giant needle valves in each valve house could jet out up to 15,500 gallons per second, shooting 450 ft to hit the opposite canyon walls. Two spillways, one on either side of the dam, have basins 650 ft long, and were fitted with four 100-ft x 16-ft drum gates. They feed into the diversion tunnels, and each can pass 200,000 cu ft of water per second, twice the maximum flow rate of Niagara Falls.

Work finished two years ahead of schedule in 1936. A total of 21,000 workers were employed during the five years of construction, with 112 deaths, including 16 who succumbed to heat exhaustion during a severe 1931 heat wave where temperatures reached 119.9° F. When the ninth of an eventual 17 generators was installed in 1939, the dam was the largest capacity hydroelectric power plant in the world. Sale of electrical power generated by the dam paid back its construction cost, with interest, by 1987.

[ad_2]

Source link

Post a Comment

You must be logged in to post a comment.