Why Every New Factory Owner Is Choosing Steel PEB Systems | ACCO Construction

Why Every New Factory Owner Is Choosing Steel PEB Systems for New Factories

🏗️ Introduction to ACCO Engineering

ACCO Engineering is a leading construction and industrial solutions provider in Pakistan, specializing in Pre-Engineered Buildings (PEB), steel structures, turnkey factory construction, industrial warehouses, and sports & leisure engineering solutions.

Based in Lahore, with projects across Pakistan, ACCO Engineering brings over two decades of technical expertise, advanced fabrication standards, and modern engineering design practices to deliver high-quality PEB buildings for factories of all types.

As industrialization accelerates in Pakistan, more factory owners are choosing ACCO Engineering for cost-effective, fast, and durable Steel PEB Systems.

🏭 Introduction: Why Factory Owners Prefer Steel PEB Systems

Across Pakistan’s industrial landscape—from Karachi to Lahore, Faisalabad, Multan, and Islamabad—new factory owners overwhelmingly prefer Steel PEB Systems over RCC (concrete) construction.

Why?

Because PEB offers:

Faster construction

Lower cost

Longer lifespan

Better structural performance

Higher flexibility

Easy expansion options

In 2025, Steel PEB Systems have become the preferred choice for new factories due to increasing industrial competition, high land costs, and the need for rapid setup.

🏗️ What Is a Steel PEB System?

A Pre-Engineered Building (PEB) is a steel structure designed, fabricated, and manufactured in a controlled factory environment.

It is then transported and assembled on-site using bolted connections.

A PEB consists of:

Primary Members

Columns

Rafters

Tapered beams

Secondary Members

Z-purlins

C-girts

Eave struts

Cladding

Pre-painted galvanized steel sheets

Sandwich panels

Accessories

Skylights

Insulation

Ventilators

Rolling shutters

Steel louvers

PEB allows large clear spans, fast construction, and customizable layouts—making them perfect for factory structures.

⚙️ H2: Key Features of Steel PEB Systems for New Factories

1️⃣ Quick Construction – 60% Faster 🚀

A traditional RCC building may take up to 12 months, while a PEB factory can be completed within 60–90 days.

Benefits:

Faster production start

Reduced labor cost

Faster return on investment

2️⃣ Low Cost – Save 25–35% 💰

PEB structures are significantly more economical because of:

✔ Light weight

✔ Less foundation requirement

✔ No shuttering

✔ Controlled factory fabrication

✔ Quick installation

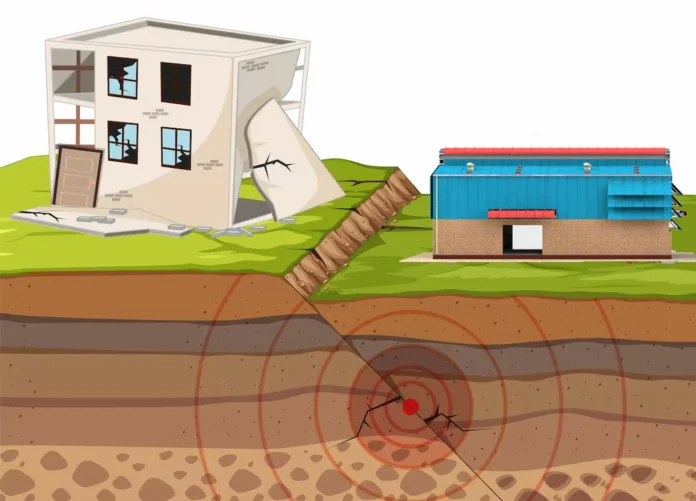

3️⃣ High Strength & Long Life 🏗️

Factory buildings built with PEB offer:

50–70 years lifespan

Earthquake resistance

High wind resistance

Durable steel components

4️⃣ Flexible Layouts – Ideal for Industries 📦

PEB allows column-free spans up to 300 ft, perfect for:

Production lines

Assembly units

Warehousing

Packaging

Forklift movement

Raw material storage

5️⃣ Crane Compatibility 🔧

Many industries require cranes for lifting heavy equipment.

PEB structures can easily support:

5 ton cranes

10 ton cranes

20–30 ton EOT cranes

6️⃣ Energy Efficiency & Temperature Control ❄️🔥

With insulated panels and ventilation systems, PEB buildings are energy-efficient and suitable for sensitive industries.

Options include:

Sandwich panels

PUF insulation

PVC-coated steel sheets

Turbo ventilators

Solar-ready roofing

📊 H2: PEB vs RCC – Comparison Table

| Feature | Steel PEB System | RCC Building |

|---|---|---|

| Construction Time | 60–90 days | 8–12 months |

| Cost | Low | High |

| Foundation | Light | Heavy |

| Flexibility | High | Low |

| Crane Support | Excellent | Moderate |

| Future Expansion | Easy | Difficult & costly |

| Maintenance | Minimal | High |

| Resale Value | High | Low |

🏭 H2: Industries Using Steel PEB for New Factories

Steel PEB systems are ideal for:

✔ Textile & Garment Factories

✔ Pharmaceuticals & Healthcare Manufacturing

✔ Food Processing & Packaging Units

✔ Cold Storage & Controlled Temperature Warehouses

✔ Logistics & Distribution Centers

✔ Automotive & Engineering Workshops

✔ Poultry Sheds & Agriculture Buildings

✔ Chemical & Paint Manufacturing Units

✔ Printing & Publishing Units

✔ IT Hardware Assembly Factories

PEB is now the industrial standard across Pakistan.

📈 H2: Latest PEB Trends in 2025

1. Hybrid Construction (RCC + PEB)

Office block in RCC + Production hall in PEB.

2. Smart IoT-Enabled Factory Buildings

Temperature sensors, fire alarms, occupancy sensors.

3. Green Energy PEBs

Solar panel roofing, insulated walls, heat-barrier systems.

4. Ultra-Wide Clear Spans

100–300 ft clear span for advanced production flow.

5. High-Load Crane-Ready PEBs

PEBs designed for multiple heavy cranes.

🔧 H2: Technical Components of a PEB Factory Building

Primary Frames

Built-up steel sections

Tapered or straight beams

Secondary Frames

Purlins

Girts

Roofing Options

Standing seam roofing

Insulated PUF roof panels

Skylight systems

Walling Options

Single skin sheets

Sandwich panels

FRP panels

Factory Accessories

Windows

Louvers

Fire RCC hydrant system

Ventilation system

✔️ Pros & Cons of Steel PEB Systems for New Factories

🌟 Pros (Advantages)

1. Fast Delivery 🚚

Significantly faster project completion.

2. Cost-Efficient 💵

Lower construction and maintenance cost.

3. Strong & Durable 🏗️

High resistance to wind, seismic activity, and corrosion.

4. Flexible Design & Expansion 🔄

Easy to expand as factory needs grow.

5. Energy Efficient ❄️☀️

Insulated panels reduce electricity bills.

6. Excellent for Industrial Cranes 🔧

Supports EOT and gantry cranes.

⚠️ Cons (Disadvantages)

1. Steel Price Instability 📉📈

Fluctuating steel prices can affect project cost.

2. Requires Skilled Fabrication 👷

Low-quality fabrication reduces structural performance.

3. Condensation Without Insulation 💧

Easily solved with proper insulation layers.

❓ Frequently Asked Questions (FAQs)

1. How long does it take to build a steel PEB factory?

Approx. 60–90 days, depending on size.

2. Are PEB buildings earthquake resistant?

Yes. Steel PEB structures perform excellently in seismic zones.

3. Is PEB cheaper than RCC?

Yes, by 25–35%.

4. Can PEB buildings support heavy cranes?

Yes. PEB is ideal for 5–30 ton crane loads.

5. Can I expand my PEB factory in the future?

Yes, PEB structures are designed for seamless expansion.

🏁 Final Verdict – Why Choose Steel PEB Systems?

Steel PEB Systems are the future of factory construction in Pakistan.

They offer:

Faster delivery

Lower cost

Strong performance

Long life

Energy efficiency

Crane compatibility

Easy expansion

For new factories, PEB is the most practical and profitable solution.

🔗 Internal Links (ACCO Engineering Website)

Industrial Construction Services – www.accoengineering.com

PEB Factory Construction Solutions – www.accoengineering.com

Warehouse & Shed Construction – www.accoengineering.com

🌍 External Links (High Authority Sources)

Pakistan Engineering Council (PEC)

DAWN News – Industrial Sector Growth

ArchDaily – Global Steel Structure Trends

📞 Call to Action (CTA)

Start Your Factory Project with ACCO Engineering Today!

📞 Call: 0322-8000190

📱 WhatsApp: 0322-8000190

🌐 Website: www.accoengineering.com

📧 Email: info@accoengineering.com

ACCO Engineering – Pakistan’s Trusted PEB & Industrial Construction Experts.

Related Posts

Post a Comment cancel reply

You must be logged in to post a comment.