Top Mistakes People Make in PEB Planning — Avoid These!

Introduction to ACCO Engineering

ACCO Engineering is Pakistan’s leading Pre-Engineered Building (PEB) manufacturer, providing modern, durable, and cost-effective steel structures across the country. Based in Gulberg-III, Lahore, our company specializes in industrial sheds, warehouses, factories, logistics hubs, poultry sheds, cold storage buildings, and commercial steel structures.

With a team of expert engineers, certified designers, and advanced fabrication technology, ACCO Engineering delivers turnkey PEB solutions — from design to erection — ensuring speed, quality, and long-term reliability.

Introduction to the Topic

Top Mistakes People Make in PEB Planning — Avoid These!

Pre-engineered buildings are rapidly growing in Pakistan due to their low cost, fast construction time, durability, and flexibility. Whether you’re building a factory, warehouse, dairy farm shed, workshop, or logistic hub, proper planning is essential to avoid delays and unnecessary costs.

Unfortunately, many clients complain that:

Their shed became more expensive than expected

The design needed changes during construction

The contractor delayed work

Material quality was not as promised

Building performance was compromised

Why does this happen?

👉 Because of poor planning and some common mistakes that most industrial owners make.

This blog explains the Top PEB Planning Mistakes and how you can avoid them with professional guidance from ACCO Engineering.

Top Mistakes People Make in PEB Planning — Avoid These!

1️⃣ Not Considering the Exact Purpose of the Building

Many clients start planning without defining the correct purpose of the building.

Every PEB shed has different structural requirements.

Examples:

Warehouse → Needs wide clear span

Factory → Needs crane beams

Cold storage → Needs insulation

Poultry shed → Needs ventilation

Workshop → Needs mezzanine floor

If the purpose is not clear, the design will be incorrect — resulting in extra costs and delays.

How ACCO Helps

We conduct a Site & Needs Assessment before design so the final structure perfectly matches your operational requirements.

2️⃣ Choosing the Wrong Building Size (Undersized or Oversized)

Many owners select building size without future planning.

❌ Undersized buildings → Expansion becomes costly

❌ Oversized structures → Unnecessary steel cost

Ideal Planning Method

Think of current needs + future expansion requirement

Plan proper clear span, height, bay spacing, and usable area

ACCO Engineering uses AutoCAD + Tekla Structure analysis to optimize building size and reduce steel cost without compromising strength.

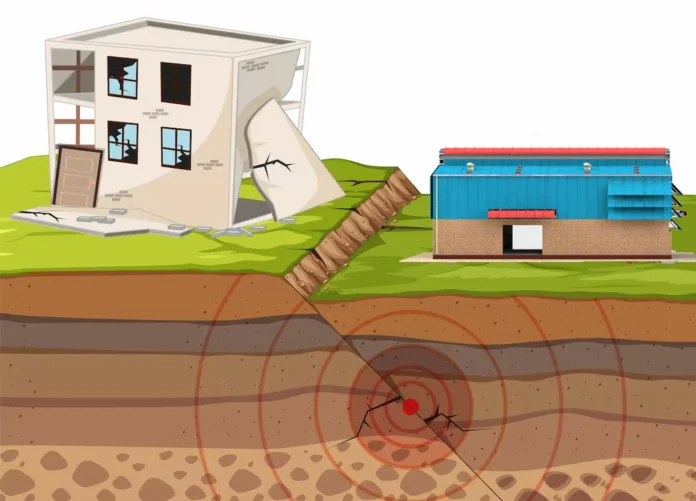

3️⃣ Ignoring Soil Testing Before Designing

A massive mistake!

Foundation design depends entirely on soil bearing capacity (SBC).

Without soil testing:

Dead load may not match the foundation

The structure may settle

Foundation cost may suddenly increase

Delays in construction occur

What You Should Do

✔ Get a proper Soil Bearing Test before design

✔ Share soil test report with the PEB design team

We always recommend clients to conduct soil testing to avoid rework and extra cost.

4️⃣ Not Considering Wind Speed & Local Weather Conditions

Pakistan has varying wind speeds:

Coastal areas (Karachi, Gwadar) → High wind speed

Punjab plains → Moderate

Northern areas → Different snow load requirements

❌ Using standard design for every location is a huge mistake.

ACCO Engineering designs each PEB as per local wind speed, climatic conditions & MBMA standards, ensuring long-term durability.

5️⃣ Selecting Inexperienced or Low-Cost Fabricators

This is one of the biggest reasons behind PEB failures.

Many fabricators offer extremely low rates, but:

They use thin steel sections

They compromise on welding quality

They skip engineering analysis

They provide poor erection workmanship

Cheap work leads to:

Leaking roof

Cracks in foundation bolts

Misaligned columns

Unsafe building

Choose Expertise, Not Low Cost

ACCO Engineering provides premium fabrication with:

Certified welders

Quality control inspectors

Laser-cut accuracy

25+ years of engineering experience

6️⃣ Poor Ventilation & Lighting Planning

Many industrial owners ignore:

Airflow needs

Natural lighting

Exhaust fans

Roof ventilators

Turbo vents

Louvers

Proper ventilation reduces heat, improves worker productivity, and lowers energy bills.

ACCO incorporates passive and active ventilation solutions in every design.

7️⃣ Not Accounting for Crane Loads

If your factory needs an overhead crane, the design must consider:

Crane capacity

Wheel loads

Column reinforcement

Bracing

Gantry girders

If planned later, the cost becomes three times higher due to structural modifications.

8️⃣ No Provision for Future Expansion

A common mistake is building without future planning.

If you need expansion later:

Existing columns may not support new load

Roof slope and direction may not match

Foundation may not support new extension

ACCO engineers design expansion-friendly structures from day one.

9️⃣ Selecting Incorrect Roof Slope or Cladding Material

Some people choose:

Wrong roof slope

Thin sheet gauge

Non-profile roofing

Poor-quality screws

No insulation

This results in:

Water leakage

Heat buildup

Poor aesthetic appeal

High maintenance cost

🔟 Not Getting a Detailed BOQ & Drawings Before Work Starts

A professional PEB project must include:

Detailed drawings

BOQ

Weight chart

Material specs

Anchor bolt plan

Erection sequence

Without documentation, misunderstandings and disputes occur.

ACCO provides complete documentation before fabrication.

Pros & Cons of Proper PEB Planning

👍 Pros (Benefits)

✔ Lower construction cost

✔ Faster project completion

✔ Long-term durability

✔ Accurate budgeting

✔ Smoother erection

✔ No design mistakes & delays

✔ Better operational efficiency

✔ Higher building resale value

👎 Cons (If Planning Is Ignored)

❌ Unexpected cost increase

❌ Design changes during construction

❌ Structural issues

❌ Unsafe building

❌ Poor ventilation & lighting

❌ Delayed completion

❌ Wastage of material

Frequently Asked Questions (FAQs)

1. What is the biggest mistake in PEB planning?

Not defining the correct purpose of the building before design.

2. How long does it take to build a PEB factory?

30–60 days for fabrication + 15–30 days for erection (depending on size).

3. Can PEB structures handle heavy machinery?

Yes, if designed properly with correct load calculations.

4. Are PEBs cheaper than RCC buildings?

Yes, typically 25–40% cheaper and much faster to build.

5. What is the ideal roof sheet thickness?

0.47 mm or 0.52 mm is preferred for durability in Pakistan.

Conclusion (Final Verdict)

Proper PEB planning is the key to successful industrial construction. Most mistakes happen due to rushed decisions, low-cost choices, and lack of technical guidance. ACCO Engineering ensures your project is designed, fabricated, and executed with professionalism, accuracy, and international standards.

If you want a high-quality, durable, and cost-effective PEB factory or warehouse, ACCO Engineering is your trusted partner.

Internal Links (Add on Website)

House Construction in DHA Lahore

Commercial Plaza Builders Lahore

PEB Structures in Pakistan

Warehouse Construction Services

External Links (Authority Sources)

Pakistan Engineering Council

DAWN Construction News

ArchDaily Structural Articles

Perfect CTA

📞 Ready to Build Your PEB Project?

Contact ACCO Engineering today for a free consultation & quotation!

📍 3rd Floor, Big City Plaza, Gulberg-III, Lahore

📞 0322 8000190

🌐 www.accoengineering.com

📩 info@acco.com.pk

Related Posts

Post a Comment cancel reply

You must be logged in to post a comment.