Pre-Engineered Steel Structures Pakistan – Durable & Cost-Effective Buildings | ACCO Construction

🏢 Introduction to ACCO Construction

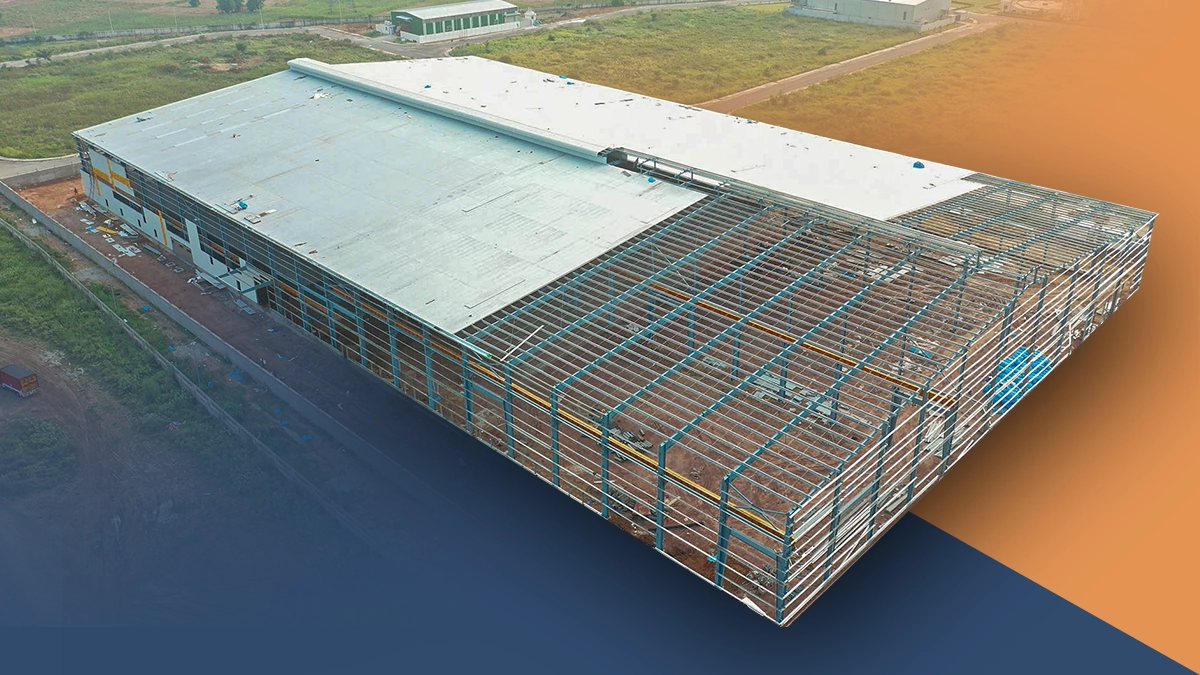

ACCO Construction is one of Pakistan’s most trusted names in industrial and commercial construction, known for delivering Pre-Engineered Steel Structures (PEB) and turnkey building solutions across the country.

Headquartered in Lahore, with active operations in Karachi, Islamabad, and Faisalabad, ACCO specializes in:

Pre-Engineered Buildings (PEB)

Industrial Sheds & Factories

Warehouses & Cold Storage Units

Steel Frame Structures

Civil, MEP & Structural Works

With years of experience in design, fabrication, and erection of steel buildings, ACCO provides cost-effective, durable, and modern building solutions that meet both local and international standards.

🧱 Introduction to the Topic: Pre-Engineered Steel Structures in Pakistan

In Pakistan’s fast-growing industrial sector, businesses are increasingly choosing Pre-Engineered Steel Structures (PEB) over conventional concrete buildings.

These structures are fabricated in factories and then assembled on-site — saving time, reducing costs, and offering superior strength and flexibility.

Industries such as manufacturing, logistics, warehousing, and agriculture are rapidly adopting PEB systems due to:

Fast construction timelines

Reduced maintenance

Long-term durability

Design flexibility

According to DAWN News, Pakistan’s industrial and logistics construction market has grown over 15% annually, driven by demand for efficient and sustainable buildings — making PEB structures the top choice for modern businesses.

🏗️ What Are Pre-Engineered Steel Structures?

A Pre-Engineered Steel Structure (PEB) is a building system designed, fabricated, and assembled using pre-manufactured steel components.

It consists of:

Primary frames: Rigid steel columns and rafters

Secondary members: Purlins, girts, and eave struts

Roof and wall panels: Corrugated steel sheets or insulated panels

Accessories: Skylights, vents, windows, and doors

🔩 Why PEBs Are Popular in Pakistan:

Quick installation

Lightweight yet durable

Ideal for large spans and open spaces

Energy-efficient and low maintenance

🔧 Types of Pre-Engineered Steel Structures

1️⃣ Industrial Sheds

Used for factories, production units, and workshops. ACCO designs sheds that offer wide column spacing for maximum floor space.

2️⃣ Warehouses

Perfect for storage and logistics companies, featuring insulation, ventilation, and fire protection systems.

3️⃣ Cold Storage Buildings

PEBs with insulated sandwich panels ensure temperature control for food, dairy, and pharmaceuticals.

4️⃣ Commercial Buildings

Modern showrooms, offices, and event halls designed using steel framing and glass façades for a premium look.

5️⃣ Aircraft Hangars & Terminals

Wide-span steel structures ideal for aviation use — designed for strength and long service life.

6️⃣ Agricultural Buildings

Steel barns, livestock shelters, and farm storage structures with corrosion-resistant materials.

🧮 Key Advantages of Pre-Engineered Steel Structures

⚡ Speed of Construction

PEBs reduce construction time by 30–50% compared to RCC buildings.

Components are fabricated in factories and quickly assembled on-site.

💰 Cost-Effective

Reduced labor and material costs.

Minimal wastage due to factory precision.

Easy transportation and assembly lower overall project expenses.

🧱 Durability & Strength

Designed to withstand earthquakes, wind loads, and harsh climates.

Long service life with minimal maintenance.

🔁 Flexibility in Design

Customizable in height, width, and layout.

Future expansions can be made easily without disrupting operations.

🌿 Eco-Friendly & Sustainable

Recyclable steel reduces carbon footprint.

Energy-efficient insulation lowers electricity consumption.

⚖️ Comparison: PEB vs Conventional RCC Construction

| Feature | Pre-Engineered Steel Structures (PEB) | Conventional RCC Buildings |

|---|---|---|

| Construction Time | 3–6 months | 9–18 months |

| Cost | 20–30% cheaper | Higher due to labor & material |

| Strength | High tensile strength | Heavy and rigid |

| Maintenance | Low | Frequent maintenance |

| Expansion | Easy and flexible | Difficult and costly |

| Sustainability | Recyclable and eco-friendly | High carbon footprint |

🏗️ The PEB Construction Process by ACCO Construction

Step 1: Concept & Design

Detailed architectural and structural design.

3D modeling and load analysis.

Step 2: Fabrication

Precision cutting and welding using CNC machines.

Quality testing for every steel component.

Step 3: Transportation

Components are shipped safely to the site with protective packaging.

Step 4: Erection & Assembly

Quick on-site installation using cranes and bolted connections.

Step 5: Finishing & Handover

Installation of wall cladding, roofing, doors, and insulation.

Final inspection and client handover.

🧰 Applications of PEB in Pakistan

🏭 Industrial Sheds & Factories

🚛 Warehouses & Logistics Centers

🧊 Cold Storage & Food Processing Units

🏢 Commercial Buildings & Offices

🚜 Agricultural Storage Facilities

🏥 Hospitals & Medical Facilities

🎓 Educational Campuses

🕌 Religious & Community Halls

PEB systems are not limited to industries — ACCO Construction has also successfully delivered PEB-based hospitals, schools, and retail complexes across Pakistan.

✅ Pros and ❌ Cons of Pre-Engineered Steel Structures

✅ Pros

Rapid construction and installation

Long lifespan (50+ years)

Earthquake and fire-resistant

Minimal maintenance

Energy-efficient insulation options

Future expandability

Recyclable and sustainable

❌ Cons

Higher initial design costs

Requires skilled labor for installation

Vulnerable to corrosion if not properly coated

Limited architectural freedom for very complex designs

❓ Frequently Asked Questions (FAQs)

1. What is the average cost of a Pre-Engineered Steel Building in Pakistan?

The cost varies between PKR 2,500 – 4,500 per sq. ft., depending on size, design, and materials used.

2. How long does it take to complete a PEB project?

Typically 3 to 6 months, which is much faster than conventional buildings.

3. Are PEBs suitable for Pakistan’s climate?

Yes, ACCO designs PEBs to withstand heat, humidity, and seismic activity specific to Pakistan.

4. Can a PEB structure be expanded in the future?

Absolutely. PEBs are modular and easily extendable.

5. Does ACCO provide turnkey PEB solutions?

Yes, ACCO handles design, fabrication, installation, and civil works — a complete turnkey package.

🧭 Final Verdict: Why Choose PEBs in Pakistan?

With industries growing and timelines tightening, Pre-Engineered Steel Structures are revolutionizing Pakistan’s construction landscape.

By offering speed, durability, flexibility, and cost savings, PEBs have become the preferred choice for factories, warehouses, and commercial buildings nationwide.

As a pioneer in PEB design and construction, ACCO Construction ensures every project meets the highest standards of safety, efficiency, and quality.

👉 Whether you need an industrial shed, cold storage facility, or multi-purpose warehouse — ACCO has the expertise to deliver it right, on time, and within budget.

🔗 Internal Links

🌐 External Links

📞 Call to Action

Ready to build your next Pre-Engineered Steel Structure in Pakistan?

Let ACCO Construction design and construct your facility with precision, speed, and quality.

📧 Email: info@acco.com.pk

📱 WhatsApp: 0322-8000190

🌐 Website: www.acco.com.pk

Related Posts

Post a Comment cancel reply

You must be logged in to post a comment.